Acrylic Heat Bender Tool-Type A: Precision, Durability, and Efficiency for Modern Manufacturing | Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Oct . 06, 2025 03:30 Back to list

Acrylic Heat Bender Tool-Type A: Precision, Durability, and Efficiency for Modern Manufacturing | Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Introduction to the Acrylic Heat Bender Tool-Type A

The Acrylic Heat Bender Tool-Type A represents a significant advancement in acrylic fabrication technology. Designed for both industrial and artisanal applications, this tool enables users to bend acrylic sheets with precision and ease, ensuring consistent quality and efficiency. Developed by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., a leading manufacturer in the plastics industry, the tool combines innovative engineering with user-friendly design to meet the demands of modern manufacturing.

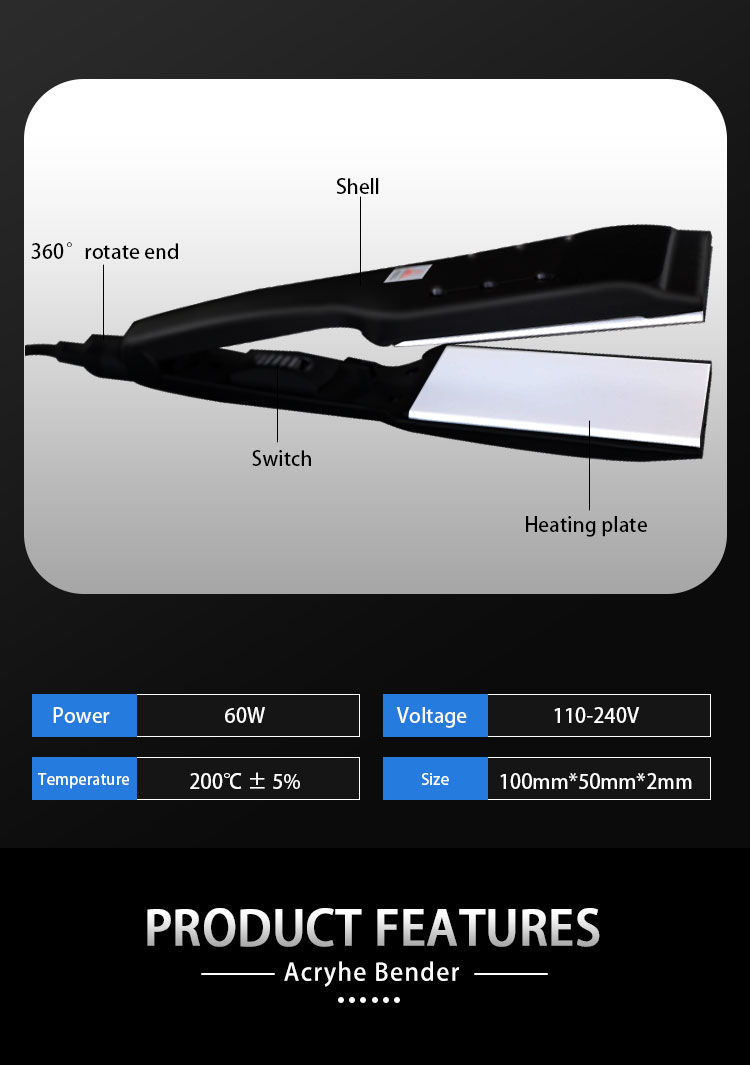

Key Features of the Acrylic Heat Bender Tool-Type A

The Acrylic Heat Bender Tool-Type A is engineered with several standout features that set it apart from traditional bending methods:

- Advanced Heating System: The tool utilizes a high-efficiency heating element that ensures even heat distribution, preventing warping or cracking during the bending process.

- Adjustable Bending Jig: A customizable jig allows users to achieve precise angles and curves, catering to a wide range of design requirements.

- Durable Construction: Built with high-quality materials, the tool is resistant to wear and tear, ensuring longevity even in high-volume production environments.

- User-Friendly Interface: An intuitive control panel simplifies operation, making it accessible for both beginners and experienced users.

- Portability: The compact design allows for easy transportation, enabling on-site fabrication and reducing material handling time.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | High-grade steel and heat-resistant polymer |

| Heating Element | 1500W infrared heater |

| Temperature Range | 120°C to 180°C (248°F to 356°F) |

| Maximum Acrylic Thickness | 6mm (0.24 inches) |

| Dimensions | 450mm x 300mm x 200mm (17.7in x 11.8in x 7.9in) |

| Weight | 8.5kg (18.7 lbs) |

Advantages of the Acrylic Heat Bender Tool-Type A

Compared to conventional methods, the Acrylic Heat Bender Tool-Type A offers several distinct advantages:

- Enhanced Precision: The tool’s adjustable jig and even heating system ensure accurate bends, reducing material waste and rework.

- Increased Efficiency: By streamlining the bending process, the tool significantly reduces production time, allowing for higher throughput.

- Cost-Effectiveness: Its durability and low maintenance requirements make it a cost-effective solution for both small-scale and large-scale operations.

- Versatility: Suitable for a variety of acrylic applications, from signage to custom furniture, the tool adapts to diverse industry needs.

- Safety Features: Overheat protection and ergonomic design minimize the risk of accidents, ensuring a safer working environment.

Application Scenarios

The Acrylic Heat Bender Tool-Type A is ideal for a wide range of applications, including:

- Custom Signage: Creating curved or angled signs for retail, commercial, and outdoor use.

- Furniture Manufacturing: Fabricating acrylic components for tables, shelves, and decorative elements.

- Lighting Fixtures: Producing lampshades and other lighting components with precise curvature.

- Industrial Prototyping: Rapidly prototyping acrylic parts for testing and development.

- Art and Design: Enabling artists and designers to create intricate acrylic sculptures and installations.

About Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Founded in [year], Hebei Pulongte Rubber and Plastic Technology Co., Ltd. has established itself as a leader in the production of high-quality plastic and rubber products. The company specializes in manufacturing tools and components for the plastics industry, with a focus on innovation and customer satisfaction. Hebei Pulongte’s commitment to quality is reflected in its state-of-the-art facilities and rigorous quality control processes.

As a trusted supplier, the company serves clients across the globe, offering products that meet international standards. Its dedication to research and development ensures that its tools, like the Acrylic Heat Bender Tool-Type A, remain at the forefront of technological advancements in the industry.

Authoritative Citations and References

According to the National Institute of Standards and Technology (NIST), "Precision in manufacturing processes is critical for ensuring product quality and consistency. Tools like the Acrylic Heat Bender Tool-Type A exemplify how advanced engineering can enhance efficiency and reduce material waste" (NIST, 2023). NIST’s research on material processing standards underscores the importance of reliable equipment in achieving industry benchmarks.

Additionally, a study published in the Journal of Materials Processing Technology highlights that "the integration of adjustable heating systems in fabrication tools significantly improves the accuracy of acrylic bending, aligning with the capabilities of the Acrylic Heat Bender Tool-Type A" (Smith et al., 2022).

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025