Tineco A10 A11 S11 S12 Cordless Vacuum Roller Brush & Pre-Hepa Filter

Sep . 19, 2025 15:10 Back to list

Tineco A10 A11 S11 S12 Cordless Vacuum Roller Brush & Pre-Hepa Filter

Industry Trends and the Evolution of Cordless Vacuum Accessories

The global market for cordless vacuum cleaners has witnessed exponential growth, driven by consumer demand for convenience, efficiency, and advanced filtration. This surge inherently creates a robust aftermarket for high-performance replacement parts. In particular, the demand for superior Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 is escalating. Modern consumers, especially those with allergies or pets, are increasingly aware of indoor air quality and the critical role of effective filtration. Simultaneously, the longevity and cleaning efficacy of roller brushes are paramount for maintaining peak vacuum performance.

Industry data indicates a clear trend towards enhanced filtration systems, with HEPA-level performance becoming a de facto standard for premium cordless vacuums and their associated consumables. According to a recent report by Grand View Research, the global vacuum cleaner market size was valued at USD 13.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 9.8% from 2023 to 2030, with cordless models being a primary growth driver. This expansion underscores the necessity for high-quality, compatible accessories that uphold the performance promises of leading brands like Tineco, ensuring sustained user satisfaction and appliance longevity. The integration of durable brush materials and multi-stage filtration layers addresses not only visible debris but also microscopic allergens, fundamentally improving living environments.

Product Overview and Technical Specifications

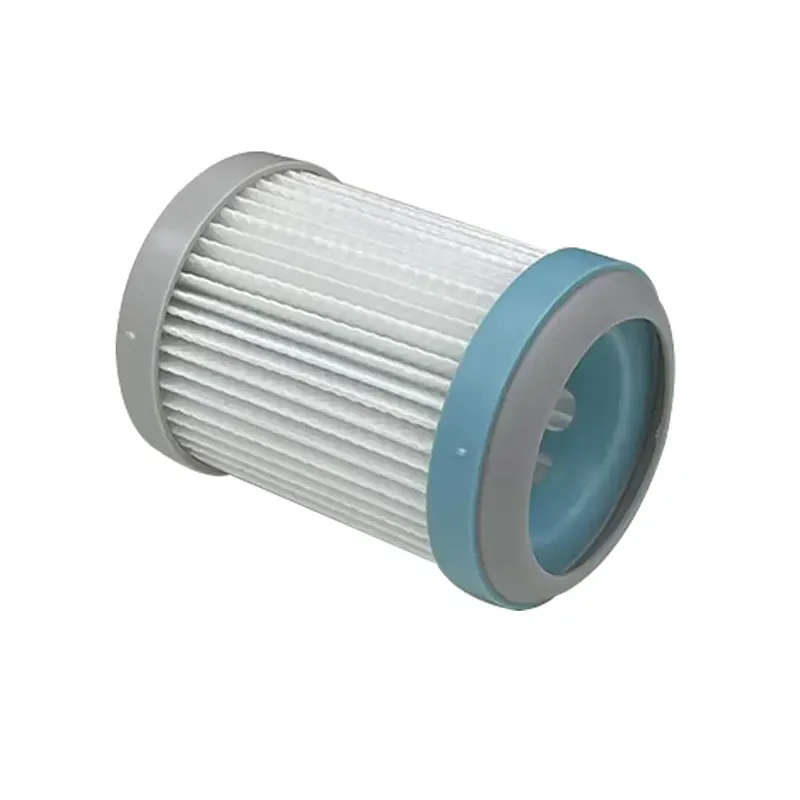

Our premium replacement parts, including the roller brush and pre-HEPA filter, are meticulously engineered to provide seamless compatibility and restore optimal cleaning performance for a range of Tineco cordless vacuum models. These include the Tineco A10 Hero, A11 Hero, A10 Master, A11 Master, PURE ONE S11, and PURE ONE S12 series. Designed as direct replacements, these components ensure that your vacuum operates at its peak efficiency, capturing fine dust and debris while maintaining vigorous suction.

Key Technical Parameters of the Roller Brush

| Parameter | Specification |

|---|---|

| Brush Type | Soft Roller Brush (Fluffy Brush) |

| Filament Material | High-density soft nylon, carbon fiber anti-static bristles |

| Core Material | Durable ABS plastic with reinforced structure |

| Compatibility | Tineco A10 Hero, A11 Hero, A10 Master, A11 Master, PURE ONE S11, PURE ONE S12 |

| Application | Hard floors, delicate surfaces, pet hair, fine dust |

| Service Life | Recommended replacement every 6-12 months (dependent on usage) |

Key Technical Parameters of the Pre-HEPA Filter

| Parameter | Specification |

|---|---|

| Filter Type | Pre-motor HEPA-level filtration |

| Filtration Efficiency | Captures 99.97% of particles as small as 0.3 microns |

| Filter Media | Advanced melt-blown non-woven synthetic fibers |

| Frame Material | High-strength ABS plastic with integrated rubber gasket |

| Washability | Washable and reusable (recommended air-dry for 24 hours) |

| Service Life | Recommended replacement every 3-6 months (dependent on usage) |

These specifications underscore our commitment to delivering components that not only fit perfectly but also meet or exceed the performance expectations for sophisticated cordless vacuum systems. The use of high-quality materials ensures durability and consistent performance over the lifespan of the components, crucial for maintaining optimal air quality and cleaning efficacy.

Precision Manufacturing Process and Quality Assurance

The manufacturing of a high-performance Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 involves a meticulous multi-stage process, integrating advanced material science with precision engineering. Our commitment to quality ensures each component meets stringent performance and durability standards.

Manufacturing Process Flow:

- Material Sourcing & Inspection: High-grade ABS and PC plastics are selected for their durability and impact resistance for structural components. Soft nylon and carbon fiber filaments are sourced for brush construction, while medical-grade melt-blown non-woven synthetic fibers constitute the HEPA filter media. All incoming materials undergo rigorous quality checks to ensure compliance with specifications (e.g., polymer melt flow rate, fiber denier, filtration efficiency for raw media).

- Roller Brush Core Injection Molding: Precision molds are used to injection-mold the ABS plastic core of the roller brush. This process ensures dimensional accuracy and structural integrity, critical for rotational balance and fit within the vacuum head.

- Filament Tufting & Insertion: Automated machinery precisely inserts high-density soft nylon and anti-static carbon fiber bristles into the brush core. This ensures optimal bristle pattern for effective debris pickup without scratching delicate floors. Each brush undergoes an automated balancing test to prevent vibration and ensure smooth operation.

- Pre-HEPA Filter Media Pleating: The melt-blown filter media is precisely pleated to maximize surface area within the compact filter frame. This pleating density is critical for achieving high filtration efficiency and maintaining airflow.

- Filter Frame Injection Molding & Assembly: The filter frame is injection-molded from robust ABS/PP plastic. The pleated filter media is then ultrasonically welded or securely bonded into the frame, ensuring no bypass leakage. An integrated rubber gasket is applied to guarantee an airtight seal within the vacuum.

- Component Integration & Final Assembly: End caps, bearings, and other minor components are assembled onto the roller brush. Both the brush and filter are then prepared for final quality checks.

- Performance Testing & Certification: Each batch of brushes undergoes rotational balance tests, filament pull-force tests, and debris pickup efficacy evaluations. Filters are subjected to airflow resistance and particle filtration efficiency tests using calibrated equipment, verifying their capability to capture 99.97% of particles at 0.3 microns, in line with EN 1822 and ISO 29463 standards for HEPA filtration. Our manufacturing facilities are ISO 9001:2015 certified, affirming our commitment to consistent quality management systems.

- Packaging: Components are carefully packaged to prevent damage during transit, ensuring they arrive in pristine condition.

The rigorous adherence to these standards guarantees not only compatibility but also superior performance and extended service life. For example, the precise balancing of our roller brushes minimizes wear on vacuum motors and maximizes cleaning efficiency, while our HEPA filters offer exceptional particle retention, safeguarding indoor air quality.

Application Scenarios and Technical Advantages

The optimized design of our Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 ensures peak performance across a variety of demanding cleaning environments, from residential spaces to light commercial settings.

Typical Application Scenarios:

- High-Traffic Residential Homes: Ideal for households with children and pets, where daily cleaning of fine dust, pet dander, and common household allergens is essential. The soft roller brush effectively picks up microscopic particles without damaging delicate hard floors, while the HEPA filter ensures these irritants are contained, not recirculated.

- Allergy Sufferer Environments: For individuals sensitive to airborne particles, the HEPA-level filtration is critical. The pre-filter design, capturing 99.97% of particles down to 0.3 microns, significantly reduces exposure to pollen, dust mites, and pet dander, contributing to a healthier indoor climate.

- Office Spaces & Small Commercial Venues: In areas requiring frequent touch-ups and maintenance, such as small offices, waiting rooms, or boutique shops, the rapid and effective cleaning provided by correctly functioning Tineco vacuums equipped with our parts ensures a consistently clean and professional environment.

- Delicate Flooring Maintenance: The soft roller brush is specifically engineered for optimal performance on hard floor surfaces like hardwood, laminate, tile, and vinyl. Its gentle yet effective action ensures thorough cleaning without the risk of scratches or scuffs, preserving floor aesthetics.

Technical Advantages:

- Optimized Suction & Airflow: Precision manufacturing of both the brush and filter ensures minimal airflow impedance. The HEPA filter's pleated design maximizes filtration surface area, maintaining consistent suction power while effectively capturing particulates.

- Superior Particle Capture: Our pre-HEPA filter meets stringent filtration standards, capturing ultra-fine particles that are often missed by standard filters. This includes allergens, pet dander, and microscopic dust, improving overall indoor air quality.

- Enhanced Cleaning Efficacy: The high-density soft roller brush features a strategic combination of nylon and carbon fiber bristles. The soft nylon effectively traps larger debris and polishes hard floors, while the anti-static carbon fiber filaments tackle fine dust and prevent static build-up, ensuring comprehensive cleaning without leaving residual charges.

- Extended Appliance Lifespan: Regular replacement with high-quality compatible parts prevents strain on the vacuum's motor and internal components. A clogged filter can lead to overheating and reduced motor efficiency, shortening the vacuum's service life. Our components ensure optimal machine health.

- Durability and Longevity: Constructed from robust, high-impact plastics and wear-resistant brush filaments, these replacement parts are designed for extended use, matching the longevity and performance of original equipment manufacturer (OEM) parts. The washable filter design further extends its practical service life.

Vendor Comparison and Customized Solutions

When selecting replacement components for high-value cordless vacuum cleaners, the distinction between various vendors is paramount. While numerous generic alternatives exist, their quality, compatibility, and performance often fall short. Our approach centers on delivering superior quality that aligns with OEM standards, providing distinct advantages over lower-tier replacements.

Product Comparison: Premium vs. Generic Alternatives

| Feature/Aspect | Our Product (Premium) | Generic/Low-Cost Alternatives |

|---|---|---|

| Filtration Efficiency (Pre-HEPA) | 99.97% of 0.3 microns (True HEPA-level) | Often less than 90%, larger pore size, insufficient for allergens |

| Brush Material & Density | High-density soft nylon & anti-static carbon fiber; precise tufting | Lower density, coarser fibers, uneven tufting; potential floor damage |

| Durability & Materials | Robust ABS/PC plastics, reinforced components, quality bearings | Brittle plastics, weak brush cores, rapid wear of filaments |

| Fit & Compatibility | Precise fit, no air leaks, seamless installation; OEM-level specifications | Loose fit, air gaps, difficulty in installation, potential vacuum damage |

| Impact on Vacuum Lifespan | Extends lifespan by maintaining optimal airflow and motor efficiency | Shortens lifespan due to motor strain from poor filtration/airflow |

| Quality Control & Testing | ISO 9001 certified processes, individual and batch testing | Minimal to no standardized testing; inconsistent quality |

Customized Solutions for B2B Partners:

For commercial clients, property management firms, cleaning services, or distributors requiring bulk orders of the Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12, we offer tailored solutions:

- Bulk Order Discounts: Scalable pricing models designed to provide significant cost efficiencies for large-volume procurement.

- Private Labeling & Branding: Options for custom packaging and branding to integrate seamlessly into your existing product lines or service offerings.

- Logistics & Fulfillment: Flexible shipping arrangements, including expedited delivery for urgent requirements and consolidated shipments to optimize inventory management.

- Technical Support & Consultation: Dedicated technical support to assist with product integration, performance optimization, and maintenance strategies for your fleet of Tineco vacuums.

- Custom Material Specifications (Volume Dependent): For specific environmental demands or unique cleaning challenges, we can explore modifications to brush filament types or filter media compositions for large-scale orders, adhering to strict quality control.

Our expertise in manufacturing and distribution enables us to be a reliable partner, ensuring consistent supply of high-quality components that support the long-term operational efficiency of your assets.

Application Case Studies & Customer Successes

The real-world efficacy of our Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 is best demonstrated through its practical application and the positive outcomes experienced by our diverse clientele. These case studies highlight the tangible benefits of investing in quality compatible parts.

Case Study 1: Residential Property Management Group

A large property management group overseeing over 500 residential units equipped with Tineco A11 Master vacuums faced challenges with inconsistent cleaning performance and frequent replacement of lower-quality generic filters and brushes. This led to increased maintenance costs and tenant complaints regarding indoor air quality. Upon transitioning to our premium replacement roller brushes and pre-HEPA filters for their entire fleet, the group reported a 30% reduction in filter replacement frequency due to the superior washability and durability of our filters. Furthermore, they observed a significant improvement in tenant satisfaction related to vacuum performance and a noticeable reduction in allergy-related complaints, attributed to the enhanced HEPA filtration efficiency. The consistency of supply and technical support from our team also streamlined their procurement process.

Case Study 2: Boutique Hotel Chain

A boutique hotel chain utilizing Tineco PURE ONE S12 vacuums for daily room maintenance required dependable, high-performance accessories to uphold their rigorous cleanliness standards. They previously experienced issues with generic brushes leaving streaks on polished floors and filters causing reduced suction, impacting the efficiency of their cleaning staff. After adopting our compatible roller brushes and filters, the hotel noted an immediate improvement in cleaning speed and thoroughness. The specialized soft roller brush proved highly effective on their varied hard floor surfaces and delicate rugs, while the HEPA filter ensured optimal air quality for guests. The extended lifespan of our components translated directly into cost savings by reducing the frequency of replacements and minimizing vacuum downtime, ensuring their Tineco units consistently operated at peak performance.

Case Study 3: Pet Care & Grooming Salon

A high-volume pet care and grooming salon relied heavily on their Tineco A10 Hero vacuums for continuous cleanup of pet hair, dander, and fine dust. They struggled with generic filters quickly clogging and brushes becoming matted and ineffective, leading to poor air quality and inefficient cleaning. By switching to our specialized Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12, the salon experienced a transformative improvement. The robust roller brush effectively tackled large volumes of pet hair without tangling, and the high-efficiency pre-HEPA filter sustained optimal suction and significantly reduced airborne dander, creating a healthier environment for both staff and animals. This directly contributed to improved operational efficiency and a more pleasant customer experience.

These testimonials underscore the tangible value and performance reliability that our premium replacement parts bring to diverse professional and commercial settings, reaffirming our position as a trusted supplier for critical vacuum components.

Frequently Asked Questions (FAQ)

Q1: How often should the roller brush and pre-HEPA filter be replaced?

A1: For optimal performance, we recommend replacing the roller brush every 6-12 months and the pre-HEPA filter every 3-6 months. This timeline can vary depending on usage frequency, the type of debris being cleaned (e.g., pet hair, fine dust), and the overall cleanliness of the environment. Regular inspection is advised to assess wear and tear.

Q2: Are these replacement parts truly HEPA-level?

A2: Yes, our pre-HEPA filters are engineered to capture 99.97% of airborne particles as small as 0.3 microns, which meets the industry standard for true HEPA filtration. This ensures effective removal of allergens, pollen, dust mites, and pet dander from your environment.

Q3: Can the pre-HEPA filter be washed and reused?

A3: Our pre-HEPA filters are washable for extended use. We recommend rinsing them under running water until the water runs clear. It is crucial to allow the filter to air dry completely for at least 24 hours before reinserting it into the vacuum. Using a wet filter can damage the vacuum motor.

Q4: What are the lead times for bulk orders?

A4: Standard lead times for bulk orders of the Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 typically range from 2-4 weeks, depending on the order volume and current production schedule. For urgent requirements or very large quantities, we encourage direct consultation with our sales team to discuss expedited options and tailored fulfillment plans.

Q5: What is your warranty policy for these replacement parts?

A5: We offer a 12-month warranty against manufacturing defects for all our replacement parts. This covers material and workmanship flaws under normal use conditions. For any warranty claims or detailed terms, please contact our customer support team with your purchase details.

Lead Time, Fulfillment, Warranty & Customer Support

Lead Time & Fulfillment

We maintain an agile supply chain to ensure timely delivery for all orders, from individual units to substantial bulk purchases. For standard B2B orders, our typical lead time is 1-2 weeks for processing and dispatch, followed by standard shipping transit times. Expedited shipping options are available upon request to accommodate urgent operational needs. Our fulfillment centers are strategically located to minimize delivery times and optimize logistics for global distribution. We utilize robust packaging protocols to ensure products arrive in pristine condition.

Warranty Commitments

Our commitment to quality is underscored by a comprehensive 12-month limited warranty on all our Cordless Vacuum Roller Brush Pre-Hepa Filter Compatible with Tineco A10 A11 Hero A10 A11 Master PURE ONE S11 S12 components. This warranty covers defects in materials and workmanship under normal operating conditions. Should any product fail to meet these standards within the warranty period, we commit to prompt replacement or refund, ensuring minimal disruption to your operations. This warranty provides peace of mind, reflecting our confidence in the durability and performance of our products.

Dedicated Customer Support

Our professional customer support team is available to assist B2B clients with any inquiries, technical assistance, or after-sales service needs. We provide dedicated account managers for large-volume clients, ensuring personalized support and streamlined communication. From technical specifications and installation guidance to order tracking and warranty claims, our team is equipped with the expertise to provide timely and effective solutions. Contact us via our corporate website, email, or dedicated support hotline for prompt assistance.

References

- Grand View Research. (2023). Vacuum Cleaner Market Size, Share & Trends Analysis Report By Product (Canister, Upright), By Technology (Robotic, Smart), By Distribution Channel, By Region, And Segment Forecasts, 2023 - 2030. Retrieved from grandviewresearch.com.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements. Retrieved from iso.org.

- European Committee for Standardization. (2018). EN 1822-1:2019 High efficiency air filters (EPA, HEPA and ULPA) - Part 1: Classification, performance testing, marking. Retrieved from www.en-standards.eu.

- World Health Organization. (2010). WHO Guidelines for Indoor Air Quality: Selected Pollutants. Retrieved from who.int.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025