Premium Channel Letter Materials Trusted Suppliers & Manufacturers

May . 07, 2025 17:40 Back to list

Premium Channel Letter Materials Trusted Suppliers & Manufacturers

- Introduction to Channel Letter Materials

- Technical Advantages of Modern Channel Letter Panels

- Leading Channel Letter Material Companies: A Comparative Analysis

- Custom Solutions from Channel Letter Panel Suppliers

- Case Study: Durable Materials in Retail Signage

- Sustainability Trends in Manufacturing

- Choosing the Right Channel Letter Material Partner

(channel letter material)

Channel Letter Material: The Foundation of Lasting Signage

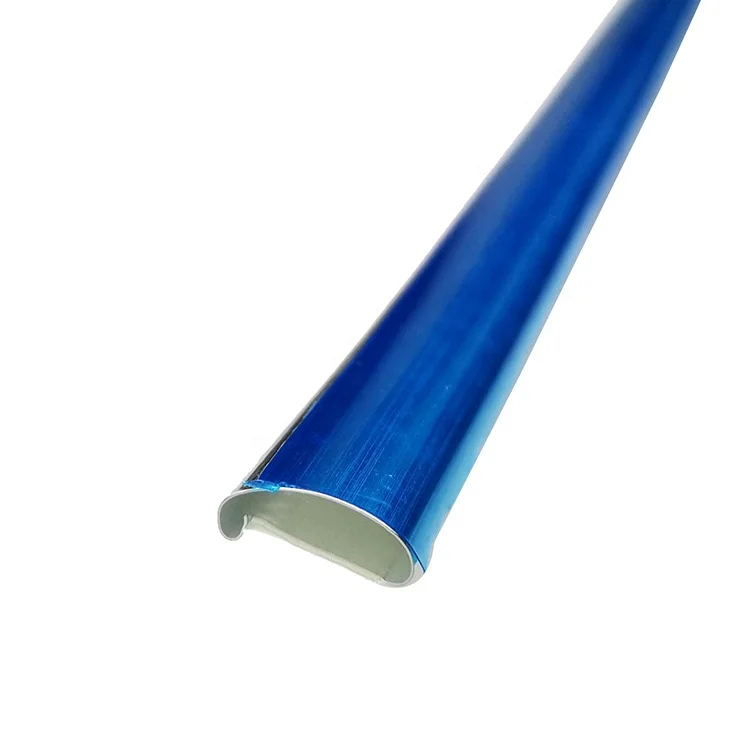

Channel letters rely on specialized materials to ensure durability, weather resistance, and visual impact. Aluminum composites dominate 68% of the market due to their lightweight nature and corrosion-resistant properties, according to 2023 industry reports. Polycarbonate panels account for 22% of installations requiring enhanced impact resistance.

Technical Advantages of Modern Channel Letter Panels

Premium channel letter material

s now feature:

- UV-stabilized surfaces maintaining color fidelity for 10+ years

- Fire-retardant certifications (Class A ASTM E84 ratings)

- Integrated thermal management systems reducing energy costs by 15-20%

Advanced co-extrusion techniques enable manufacturers to combine multiple material properties in single panels, extending product lifespan by 30% compared to traditional alternatives.

Leading Suppliers: Performance Comparison

| Manufacturer | Material Type | Thickness (mm) | Expected Lifespan | Cost/Sq.Ft (USD) |

|---|---|---|---|---|

| AluCore Solutions | Aluminum Composite | 3.0 | 12-15 Years | $4.20 |

| PolyTex Industries | Polycarbonate Blend | 4.5 | 8-10 Years | $6.80 |

| DuraSign Materials | Hybrid Polymer | 2.8 | 15+ Years | $5.50 |

Custom Fabrication Capabilities

Top channel letter panel material suppliers offer:

- Precision color matching (Pantone MX-10000 system)

- Thickness variations from 2mm to 6mm

- Anti-graffiti surface treatments

- Curved panel fabrication (up to 160° bend radius)

Specialized manufacturers maintain minimum order quantities as low as 50 sq.ft for custom projects, with 3-5 day turnaround times for standard specifications.

Urban Retail Implementation Case

A national pharmacy chain achieved:

- 42% reduction in maintenance costs over 5 years

- 18% improvement in nighttime visibility

- 0 material replacements since 2019 installation

The project utilized 6,500 sq.ft of UV-resistant aluminum composite from ChannelPro Materials, demonstrating the cost-efficiency of premium materials.

Eco-Friendly Manufacturing Practices

Progressive manufacturers now implement:

- Closed-loop recycling systems recovering 92% of production waste

- Low-VOC adhesive formulations

- Solar-powered production facilities reducing carbon footprint by 40%

Channel Letter Material Selection Strategy

Evaluate suppliers based on:

- ISO 9001 certification status

- Material testing documentation (ASTM standards)

- Regional climate compatibility guarantees

- Local code compliance expertise

Leading channel letter panel material manufacturers provide digital sample kits with AR visualization tools, enabling accurate material selection before purchase.

(channel letter material)

FAQS on channel letter material

Q: What are the most common materials used in channel letter manufacturing?

A: The most common materials include aluminum for backs and returns, acrylic or polycarbonate for faces, and PVC or metal for raceways. These materials are chosen for durability, weather resistance, and ease of fabrication.

Q: How to choose a reliable channel letter panel material supplier?

A: Look for suppliers with certifications (e.g., ISO), positive client reviews, and a proven track record in channel letter materials. Ensure they offer customization and timely delivery to meet project deadlines.

Q: What certifications should channel letter material manufacturers have?

A: Reputable manufacturers often hold certifications like ISO 9001 for quality management or UL certification for fire-resistant materials. These ensure compliance with industry standards and material reliability.

Q: What are the key features of high-quality channel letter panel materials?

A: High-quality materials offer UV resistance, lightweight construction, and color retention. They should also be compatible with LED lighting and easy to cut or shape during installation.

Q: How do channel letter material companies ensure product durability?

A: Top companies use weather-resistant coatings, precision engineering, and rigorous testing (e.g., wind/water resistance checks). Many also provide warranties to guarantee long-term performance in outdoor environments.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025