Leading Window Seal Strip Adhesive Solutions & Companies

Aug . 17, 2025 01:20 Back to list

Leading Window Seal Strip Adhesive Solutions & Companies

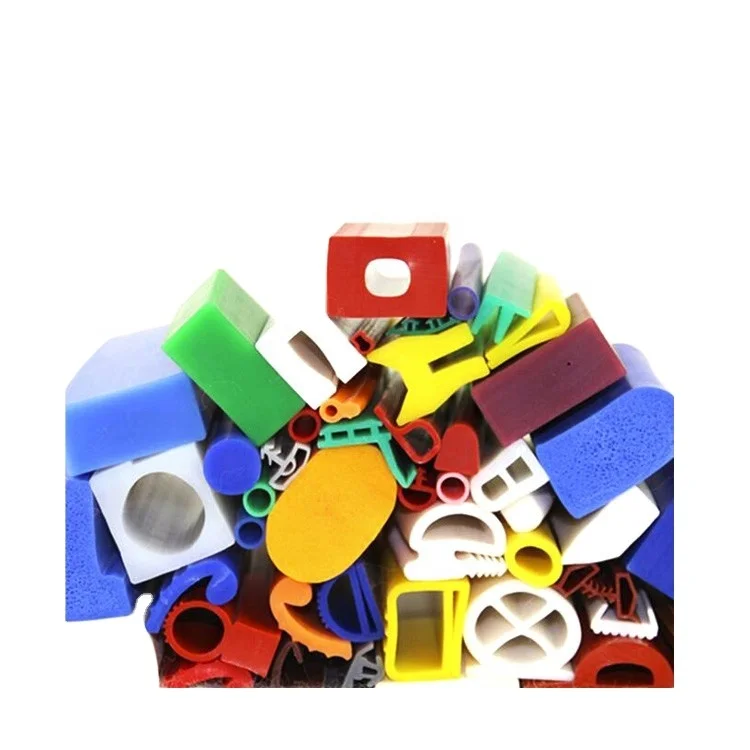

The Crucial Role of Advanced Sealing Solutions in Modern Industries

In an era driven by energy efficiency, enhanced safety, and operational precision, the significance of high-performance sealing solutions cannot be overstated. From consumer appliances to heavy industrial machinery, robust sealing mechanisms are fundamental to preventing energy loss, containing critical media, and ensuring system integrity. The market for sophisticated sealing components, particularly silicone and EPDM based products, is experiencing continuous growth, driven by escalating demands for materials capable of withstanding extreme temperatures, harsh chemicals, and prolonged mechanical stress. This trend underscores the vital role played by leading window seal strip adhesive companies, which are at the forefront of innovating and manufacturing the advanced materials critical for these applications. These specialized firms are not merely suppliers; they are key partners in achieving operational excellence across diverse sectors, including automotive, construction, HVAC, and white goods manufacturing, by delivering tailored solutions that meet stringent industry standards and performance benchmarks.

The evolving landscape of industrial design and operational requirements necessitates a deeper understanding of the technical specifications and application nuances of sealing products. Modern sealing strips are engineered to perform under challenging conditions, offering superior resistance to aging, ozone, UV radiation, and a wide array of chemical agents. For instance, the demand for high-temperature resistant sealing strips, such as the High temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven door, reflects a growing need in sectors like food processing, industrial ovens, and specialized heating equipment. These products are designed to maintain their elasticity and sealing effectiveness even when exposed to temperatures exceeding 250°C, a critical factor for both safety and energy conservation. The expertise of a proficient window seal strip adhesive manufacturer lies in their capacity to not only produce these materials but also to meticulously test and validate their performance characteristics, ensuring they adhere to international quality and safety protocols. Their contributions are pivotal in enabling manufacturers to develop more efficient, durable, and safer products, thereby driving innovation and sustainability across various industries.

Precision Manufacturing and Rigorous Quality Control

The production of high-performance sealing strips, especially those designed for high-temperature applications, involves a sophisticated multi-stage manufacturing process. This journey typically begins with the meticulous selection and compounding of raw materials. For silicone rubber strips, this includes high-grade silicone polymers, reinforcing fillers like fumed silica, processing aids, and vulcanizing agents. These components are precisely weighed and mixed in internal mixers or two-roll mills to achieve a homogenous compound with specific mechanical properties. The consistency of this compound is paramount, as it directly influences the final product's performance attributes such as hardness, tensile strength, and elongation. Leading window seal strip adhesive factories leverage advanced compounding techniques to optimize material properties for extreme operating conditions, ensuring a foundational quality that permeates the entire product lifecycle.

Following compounding, the material undergoes a shaping process, predominantly extrusion for continuous profiles like E or P shapes. In extrusion, the compounded rubber is fed into an extruder, where it is heated and forced through a die to form the desired cross-sectional profile. This method ensures consistent dimensions and a smooth surface finish. Subsequent to extrusion, the uncured profile is then subjected to vulcanization (curing), a critical process where the rubber is cross-linked under heat and pressure, transforming it from a pliable plastic-like material into a durable, elastic rubber. This stage determines the material's permanent set, resilience, and resistance to temperature and chemicals. For high-temperature applications, post-curing might be employed to further enhance thermal stability and reduce volatile compounds, ensuring the product's longevity and performance in demanding environments like oven doors. Adherence to standards such as ISO 9001 for quality management and ASTM D2000 for rubber products classification is non-negotiable for reputable window seal strip adhesive companies, guaranteeing consistent quality and reliability.

Quality assurance is integrated at every step of the manufacturing pipeline. Initial material inspections verify the purity and consistency of raw polymers. During extrusion, inline monitoring systems ensure dimensional accuracy. Post-vulcanization, finished products undergo a series of rigorous tests. These include Shore A hardness testing (ASTM D2240) to verify flexibility and resistance to indentation, tensile strength and elongation at break (ASTM D412) to assess material strength and elasticity, and compression set testing (ASTM D395) to measure the material's ability to return to its original thickness after prolonged compression, which is crucial for maintaining sealing effectiveness over time. Accelerated aging tests, such as heat aging (ASTM D573), simulate long-term exposure to high temperatures to predict service life and validate performance claims. For specific applications like oven doors, flame retardancy (UL94) and FDA compliance for food contact materials are also critical inspection points. This comprehensive testing regime ensures that each batch of product, particularly specialized items like the High temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven door, meets or exceeds the specified technical parameters and industry benchmarks, guaranteeing robust performance and an extended service life in demanding operational environments.

Technical Specifications and Performance Metrics

Understanding the detailed technical parameters of sealing strips is crucial for engineers and procurement specialists to select the optimal product for their specific application. For the High temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven door, key performance indicators include its remarkable thermal stability, typically rated for continuous operation from -60°C to +250°C, with intermittent peaks potentially higher. This wide operating range makes it ideal for environments where extreme temperature fluctuations are common. The Shore A hardness typically ranges from 40 to 70 durometer, offering a balance between flexibility for ease of installation and sufficient rigidity to maintain effective sealing pressure. Silicone's inherent properties also provide excellent resistance to ozone, UV light, weathering, and a broad spectrum of chemicals, including dilute acids, bases, and many oils, distinguishing it from general-purpose rubbers. The unique E and P shapes are engineered to provide optimal compression and create multiple sealing points, further enhancing their effectiveness in preventing heat loss or ingress of contaminants, a design characteristic highly valued by discerning window seal strip adhesive suppliers and their clients.

To further illustrate the advantages and distinct characteristics of various sealing materials and typical product offerings from reliable window seal strip adhesive exporters, consider the comparative data below. This table highlights how silicone rubber, especially the high-temperature resistant variants, offers superior performance in critical areas compared to other common elastomers like EPDM or Neoprene, particularly concerning thermal stability and environmental resilience. Such detailed comparisons empower B2B buyers to make informed decisions, prioritizing long-term performance and total cost of ownership over initial acquisition cost. The application of pressure-sensitive adhesives (PSAs) to these strips further simplifies installation and enhances immediate adhesion, albeit the primary sealing function is delivered by the strip's mechanical compression. The integration of high-quality PSAs, designed to maintain integrity across the strip's operating temperature range, represents a significant technical advantage offered by leading window seal strip adhesive manufacturers.

| Property | Silicone Rubber (HT) | EPDM | Neoprene (CR) |

|---|---|---|---|

| Operating Temperature Range (°C) | -60 to +250 (up to 300 intermittent) | -40 to +150 | -40 to +120 |

| Ozone & UV Resistance | Excellent | Excellent | Good |

| Chemical Resistance (General) | Good (acids, alkalis) | Good (water, some acids) | Fair (oils, solvents) |

| Compression Set | Excellent | Good | Fair to Good |

| Flame Retardancy | Inherently low smoke/toxicity | Can be formulated | Self-extinguishing |

| Cost Efficiency (Relative) | Higher (due to performance) | Medium | Medium |

Versatile Applications and Tangible Benefits

The application spectrum for high-performance window seal strip adhesives extends far beyond conventional window frames, reaching into diverse industrial sectors where sealing integrity is paramount. For example, the High temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven door finds its primary utility in commercial and industrial ovens, furnaces, and other high-temperature processing equipment. Its ability to maintain a tight seal at elevated temperatures significantly reduces heat loss, thereby contributing to substantial energy savings and optimizing operational efficiency. Beyond thermal applications, these advanced sealing solutions are indispensable in the automotive industry for engine compartments, lighting fixtures, and body seals, where they resist vibrations, weather, and chemicals. In the construction sector, specialized seal strips are used in expansion joints, curtain walls, and fire-rated doors to provide superior thermal, acoustic, and smoke barriers. The versatility of these products underscores why leading window seal strip adhesive companies are continuously innovating to meet the evolving demands of various industries, ensuring safety and performance.

The technical advantages offered by meticulously engineered sealing strips translate into tangible economic and operational benefits for businesses. Firstly, the superior thermal insulation properties of silicone rubber minimize heat transfer, leading to reduced energy consumption in heating or cooling applications. This directly impacts operational costs and contributes to environmental sustainability goals. Secondly, these seals provide excellent protection against dust, moisture, and chemical ingress, safeguarding sensitive components and extending the service life of equipment. In environments prone to vibration or noise, such as machinery enclosures or vehicle cabins, the damping properties of rubber seals contribute to a quieter and more stable operation. For critical applications like those requiring high integrity, such as in the petrochemical or pharmaceutical industries, specialized seals prevent hazardous leaks, ensuring compliance with stringent safety regulations (e.g., ANSI standards for piping systems where such seals might be indirectly related through ancillary equipment). The strategic deployment of high-quality window seal strip adhesive products is thus a critical investment in efficiency, safety, and durability, enhancing overall system reliability and reducing maintenance requirements across a wide range of industrial and commercial settings.

Choosing the Right Partner: Manufacturer Comparison and Custom Solutions

Selecting the ideal window seal strip adhesive manufacturer is a strategic decision that directly impacts product quality, supply chain reliability, and ultimately, operational success. When evaluating potential partners, B2B buyers should look beyond mere price points and delve into the manufacturer's technical capabilities, track record, and commitment to innovation. Key considerations include the depth of their R&D department, their ability to conduct in-house testing and validation, and their adherence to international quality standards such as ISO 9001 and IATF 16949 (for automotive applications). A manufacturer with extensive experience in the field will not only offer a broad portfolio of standard window seal strip adhesive products but also possess the expertise to provide nuanced advice on material selection, design optimization, and application best practices. Furthermore, assessing their production capacity and lead times is essential for ensuring timely delivery and avoiding costly project delays, making thorough vetting of window seal strip adhesive exporters a crucial step.

One of the most significant advantages offered by top-tier window seal strip adhesive companies is their capacity for customization. While standard profiles like E and P shapes are versatile, many industrial applications require bespoke solutions to achieve optimal sealing performance. Customization options typically include unique cross-sectional designs, specific material formulations to resist particular chemicals or temperature extremes, specialized adhesive backing for diverse surface types, and precise cut-to-length options to minimize waste and simplify assembly. A reputable manufacturer will engage in a collaborative design process, often utilizing CAD/CAM software to develop prototypes and conduct simulations, ensuring the custom solution perfectly aligns with the client's engineering specifications. For instance, for an industrial oven door, the precise shape, durometer, and adhesive type can be fine-tuned to ensure maximum thermal efficiency and extended service life under continuous high-temperature exposure. This bespoke approach not only enhances product performance but also integrates seamlessly into the client's production processes, distinguishing market leaders among window seal strip adhesive factories from general suppliers. It's also worth noting that competitive window seal strip adhesive quotes for custom solutions reflect the value of engineering expertise rather than just raw material cost.

Real-World Impact: Case Studies and Client Success

The practical effectiveness of advanced sealing solutions is best demonstrated through real-world application cases. Consider a prominent European appliance manufacturer that sought to improve the energy efficiency and lifespan of their commercial-grade ovens. Their existing sealing strips were failing prematurely under continuous high-temperature cycles, leading to significant heat loss and increased warranty claims. Upon partnering with a specialized window seal strip adhesive company, they adopted the High temperature resistant E P shaped silicone rubber sealing strip rubber gasket. The custom-engineered silicone gasket, designed with specific compression characteristics and optimized adhesive, demonstrated exceptional thermal stability and minimal compression set even after thousands of operational cycles. This resulted in a measured 15% reduction in energy consumption per oven and a remarkable 40% decrease in sealing-related service calls over a three-year period, validating the superior performance and durability of the advanced silicone solution provided by a leading window seal strip adhesive supplier.

Another compelling example comes from the industrial HVAC sector. A manufacturer of large-scale air handling units faced challenges with air leakage and noise transmission through access panel seals, affecting system efficiency and indoor air quality. Traditional EPDM foam strips were degrading quickly under constant air pressure and environmental exposure. A trusted window seal strip adhesive factory provided a custom-formulated dense silicone seal strip with a pressure-sensitive adhesive backing, engineered to withstand continuous air movement and varying humidity levels. The new silicone seals significantly improved the airtightness of the units, reducing energy waste by an estimated 10% and improving the acoustic performance. Customer feedback highlighted the enhanced durability and reduced need for maintenance, reinforcing the manufacturer's reputation for quality. These cases underscore that engaging with experienced window seal strip adhesive exporters who offer a consultative approach and proven products is a strategic decision that yields substantial and measurable returns on investment, leading to long-term operational benefits and client satisfaction.

Ensuring Trust: FAQs, Delivery, and Warranty Commitments

Building trust with B2B clients extends beyond product quality to encompass transparent communication, reliable logistics, and steadfast after-sales support. Reputable window seal strip adhesive companies prioritize these aspects to foster long-term partnerships. A comprehensive FAQ section can address common concerns proactively, from material compatibility to installation guidelines. For instance, questions often arise regarding the lifespan of silicone seals, which typically exceeds 10-20 years in many applications due to its excellent resistance to aging, or optimal adhesive application techniques. Clarifying these points upfront demonstrates expertise and commitment to customer education. Furthermore, clear communication regarding delivery cycles is essential for inventory management and production planning. Leading suppliers maintain efficient logistics networks, offering various shipping options and providing accurate lead times, often ranging from 2-4 weeks for standard products and 4-8 weeks for highly customized orders, depending on complexity and volume.

A strong warranty commitment further solidifies a manufacturer's trustworthiness. A standard warranty for high-quality silicone sealing strips typically covers manufacturing defects for a period of 1 to 5 years, depending on the product's intended application and expected service conditions. Beyond the warranty, responsive customer support is critical. This includes technical assistance for installation issues, troubleshooting product performance, and facilitating reorders or modifications. Companies that provide dedicated account managers and accessible technical support teams ensure that clients receive timely and effective solutions, minimizing downtime and maximizing operational continuity. This holistic approach, encompassing comprehensive pre-sales consultation, transparent delivery processes, and robust post-sales support, differentiates the most reliable window seal strip adhesive companies in a competitive global market, reinforcing their role as trusted partners for industrial sealing solutions.

Frequently Asked Questions (FAQs)

- What is the typical lifespan of a silicone window seal strip in a high-temperature application?

High-quality silicone seals like the High temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven door are engineered for exceptional durability, often exceeding 10-20 years in continuous high-temperature service due to silicone's inherent resistance to heat aging, ozone, and UV degradation. - Are these sealing strips resistant to chemicals?

Silicone rubber offers good resistance to a wide range of chemicals, including dilute acids, bases, and many oxidizing agents. However, specific resistance can vary, so it's always recommended to consult the manufacturer for compatibility with unique chemical exposures. - Can these seals be customized for specific dimensions or profiles?

Absolutely. Most reputable window seal strip adhesive manufacturers offer extensive customization services, allowing for bespoke profiles, specific material formulations, custom colors, and precise cut-to-length options to meet unique application requirements. - What are the common inspection standards adhered to by reputable manufacturers?

Leading window seal strip adhesive factories typically comply with international standards such as ISO 9001 for quality management, ASTM D2000 for rubber product classification, and often industry-specific certifications like FDA for food-grade applications or UL for flame retardancy. - How important is the adhesive backing for the seal's performance?

While the primary sealing function comes from the strip's mechanical compression, the adhesive backing plays a crucial role in initial positioning and maintaining the strip's placement during installation and operation. High-quality adhesives are designed to withstand the same temperature ranges as the silicone strip itself.

Conclusion: Partnering for Sealing Excellence

The demand for high-performance sealing solutions, exemplified by products like the High temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven door, continues to escalate across a multitude of industrial and commercial applications. From enhancing energy efficiency in high-temperature ovens to ensuring safety in critical industrial systems, the efficacy of these components is undeniable. The expertise, experience, and commitment of specialized window seal strip adhesive companies are paramount in delivering solutions that not only meet but exceed rigorous performance expectations. Their comprehensive approach, spanning from material science and precision manufacturing to tailored customization and unwavering customer support, establishes them as indispensable partners in achieving operational excellence.

By emphasizing strict adherence to international quality standards, investing in advanced testing methodologies, and fostering a culture of continuous innovation, leading window seal strip adhesive companies empower industries to build more durable, energy-efficient, and safer products. For B2B decision-makers and technical personnel, choosing a supplier with a proven track record of reliability, technical depth, and a customer-centric philosophy is crucial. This strategic partnership ensures access to cutting-edge sealing technology that will stand the test of time and demanding environments, ultimately contributing to enhanced product longevity, reduced operational costs, and sustainable industrial growth.

References

- American Society for Testing and Materials (ASTM) Standards for Rubber, particularly D2000, D2240, D412, D395, D573.

- International Organization for Standardization (ISO) 9001:2015 - Quality Management Systems.

- Rubber Manufacturers Association (RMA) Handbook.

- United States Food and Drug Administration (FDA) CFR 21 - Indirect Food Additives: Polymers.

- Underwriters Laboratories (UL) 94 - Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025