Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

Aug . 26, 2025 02:00 Back to list

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

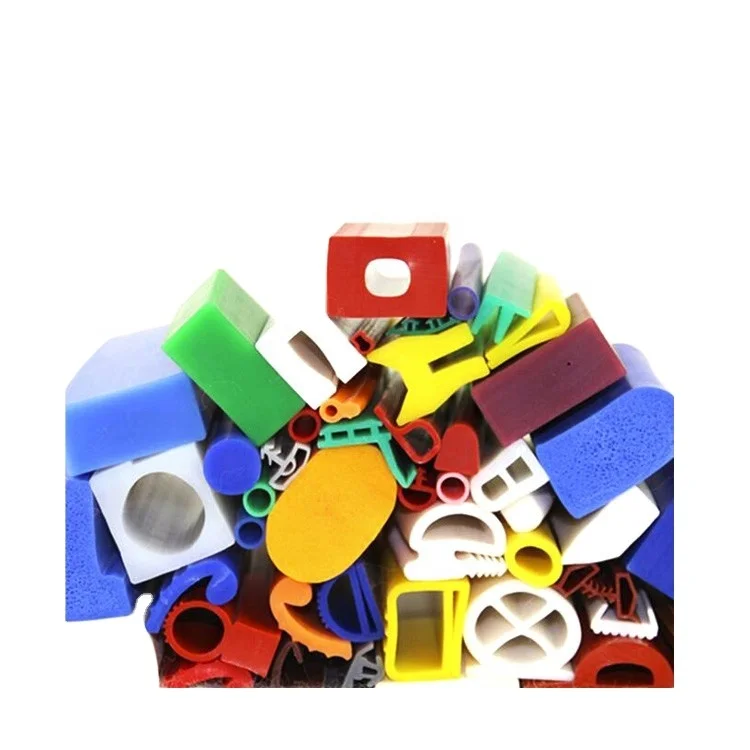

The Crucial Role of Advanced Sealing Solutions in Industrial Operations

In the demanding landscape of industrial manufacturing and infrastructure, the integrity of sealing solutions is paramount. From maintaining critical process temperatures to ensuring environmental protection and operational efficiency, high-performance seals are non-negotiable. This necessitates a deep understanding of the capabilities offered by leading window seal strip adhesive companies that specialize in innovative gasket and sealing strip technologies.

The selection of appropriate sealing components directly impacts energy consumption, equipment longevity, and overall operational safety. As industries evolve, the demand for materials capable of withstanding extreme temperatures, corrosive environments, and continuous mechanical stress has surged. This article delves into the technical aspects, manufacturing processes, application benefits, and vendor considerations for advanced sealing solutions, focusing on products like the high-temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven doors.

Industry Trends Driving Innovation in Sealing Technologies

The sealing industry is currently shaped by several key trends:

- High-Performance Materials: Increasing adoption of specialty elastomers like silicone, FKM, and FFKM for superior thermal, chemical, and environmental resistance. This is crucial for applications demanding extreme durability.

- Energy Efficiency: A strong push for seals that minimize energy loss in high-temperature or pressure systems, contributing to sustainability goals and cost savings.

- Miniaturization and Precision: Growing demand for seals in smaller, more intricate assemblies requiring exceptionally tight tolerances and advanced manufacturing techniques.

- Smart Sealing Solutions: Emergence of seals with integrated sensors for real-time monitoring of performance, temperature, or pressure, enabling predictive maintenance.

- Environmental Compliance: Adherence to stringent regulations (e.g., RoHS, REACH, FDA) for material safety and environmental impact, particularly relevant for `window seal strip adhesive products` used in sensitive applications.

These trends underscore the necessity for robust research and development by `window seal strip adhesive manufacturers` to meet evolving industrial requirements.

The Manufacturing Process: From Raw Material to Advanced Seal

The production of high-quality silicone rubber sealing strips involves a meticulous multi-stage process, ensuring precision and consistent performance:

Process Flow Diagram:

Mixing high-purity silicone polymers with reinforcing fillers (e.g., fumed silica), pigments, cross-linking agents, and processing aids to achieve desired properties (e.g., high-temp resistance, specific hardness).

The compounded silicone is fed into an extruder or compression molding press. For profiles like E P shapes, extrusion is common. The material is forced through a die to form the continuous cross-sectional shape.

The formed profile undergoes heat treatment (vulcanization) to cross-link the polymer chains, transforming the soft compound into a durable, elastic rubber with its final mechanical properties. This can be done in hot air ovens or through continuous curing lines.

For self-adhesive strips, a high-temperature resistant adhesive layer (e.g., acrylic or silicone-based pressure-sensitive adhesive) is applied to one surface, often with a release liner for protection.

The continuous strip is cut to specified lengths, or processed into endless gaskets through splicing techniques. Final inspection and packaging follow.

Throughout the process, rigorous testing is conducted, including dimensional checks, hardness (Shore A), tensile strength, elongation at break, compression set, and specific gravity, often adhering to ISO 9001 and industry-specific standards.

This systematic approach ensures that products from `window seal strip adhesive factories` meet stringent performance requirements.

Technical Specifications & Performance Parameters (Expertise)

Understanding the technical specifications of a sealing strip is critical for engineers and procurement specialists. For the high temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven door, key parameters include:

| Parameter | Typical Value (Silicone Rubber) | Significance for Oven Doors |

|---|---|---|

| Material | High-Purity Silicone Rubber (VMQ) | Excellent thermal stability, low toxicity, and flexibility across wide temperature ranges. |

| Operating Temperature Range | -60°C to +250°C (up to +300°C short-term) | Crucial for maintaining integrity and sealing efficiency in high-temperature oven environments. |

| Hardness (Shore A) | 40-70 (typically 50-60 for seals) | Affects compression, sealing force, and resistance to deformation under load. Softer seals conform better, harder seals offer more resistance to abrasion. |

| Tensile Strength | 5-10 MPa (725-1450 psi) | Indicates the material's resistance to breaking under tension, important for durability during installation and use. |

| Elongation at Break | 200-500% | Measures the material's flexibility and ability to stretch before breaking, beneficial for fitting and absorbing movement. |

| Compression Set (22h @ 175°C) | Typically | A low compression set ensures the seal retains its elastic properties and sealing force over time, even after prolonged compression at high temperatures. Critical for long service life. |

| Specific Gravity | 1.10 - 1.25 g/cm³ | Indicates material density. Useful for weight calculations and material identification. |

| Adhesive Type (if applicable) | High-Temp Silicone PSA or Acrylic PSA | Ensures secure, long-lasting attachment to the oven door or frame, maintaining adhesion at elevated temperatures. |

The E P shape profile is specifically designed to provide multiple sealing points and excellent compression recovery, making it ideal for oven doors where thermal expansion and contraction are significant factors. These specifications highlight the advanced engineering behind robust `window seal strip adhesive products`.

Application Scenarios and Technical Advantages (Experience)

High-performance silicone sealing strips find extensive use across various demanding industrial sectors:

- Industrial Ovens & Furnaces: Essential for sealing oven doors, curing ovens, and industrial furnaces, preventing heat loss and maintaining stable internal temperatures. This directly contributes to energy saving and consistent product quality.

- HVAC Systems & Cleanrooms: Used for sealing access panels, ductwork, and filters, ensuring air-tightness and preventing contaminants from entering critical environments.

- Automotive Industry: Gaskets for engine compartments, window seals, and various component seals requiring resistance to heat, oil, and ozone.

- Electronics & Electrical Enclosures: Sealing electrical cabinets and outdoor enclosures against dust, moisture, and temperature fluctuations, ensuring component longevity and safety.

- Food Processing Equipment: FDA-compliant silicone seals are vital for hygienic sealing in ovens, proofers, and cold storage units, offering chemical inertness and ease of cleaning.

- Petrochemical & Metallurgy: While primary applications for these sectors often involve more rigid materials, specialized high-temp silicone can be used in certain ancillary equipment where flexibility and high-temperature resistance are key, offering corrosion resistance against some chemicals.

- General Industrial Equipment: Anywhere a robust, durable seal is required to handle high temperatures, UV exposure, or environmental extremes, such as machinery covers, inspection hatches, and access panels.

The technical advantages are substantial:

- Superior Thermal Stability: Silicone maintains its elasticity and sealing properties over an extremely wide temperature range, significantly outperforming organic rubbers.

- Excellent Weathering Resistance: Unaffected by UV light, ozone, and extreme weather, leading to a long service life even in outdoor applications.

- Chemical Inertness: Resistant to many chemicals, solvents, and oils, although specific compatibility should always be verified.

- Low Compression Set: Ensures the seal retains its shape and sealing force over prolonged periods, reducing the need for frequent replacement.

- Energy Saving: Effective sealing of high-temperature equipment minimizes heat loss, leading to significant reductions in energy consumption.

- Vibration Damping: Silicone's elasticity helps absorb vibrations, reducing noise and wear on equipment.

Leading `window seal strip adhesive suppliers` focus on delivering products that embody these critical advantages.

Vendor Comparison and Customized Solutions (Authoritativeness)

Selecting the right `window seal strip adhesive exporter` or manufacturer requires careful evaluation beyond just price. Key factors include:

- Material Quality & Traceability: Ensuring the use of virgin, high-grade polymers with full traceability.

- Manufacturing Capabilities: Precision extrusion, molding, and finishing capabilities for complex profiles and tight tolerances.

- Quality Certifications: ISO 9001 for quality management, ISO 14001 for environmental management, and product-specific certifications like FDA, RoHS, REACH, UL.

- Technical Support & R&D: Ability to provide engineering assistance for material selection, design optimization, and custom tooling.

- Customization Options: Offering bespoke solutions in terms of profiles (e.g., E, P, D, L, U shapes), dimensions, specific colors, durometers, and specialized adhesive backing.

- Lead Time & Logistics: Reliable production schedules and efficient global shipping for timely project completion.

Comparison of Silicone Seal Grades:

| Feature | Standard Grade Silicone (e.g., VMQ) | High-Temp/Specialty Silicone (e.g., FVMQ, PVMQ) | Fluorosilicone (FVMQ) |

|---|---|---|---|

| Max Temp (Continuous) | 200-230°C | 250-300°C | 200°C |

| Chemical Resistance | Good (Water, dilute acids/bases) | Very Good (Improved against some chemicals) | Excellent (Fuels, oils, solvents) |

| Oil Resistance | Poor to Fair | Fair to Good | Excellent |

| Cost | Moderate | Higher | Highest |

| Typical Application | General purpose, oven doors, weatherseals | Extreme high-temp ovens, critical industrial seals | Aerospace, automotive fuel systems |

For instance, a reputable `window seal strip adhesive company` often collaborates closely with clients to develop custom profiles and material formulations, ensuring the seal perfectly matches the application's unique geometry and performance demands. This includes considerations for specific adhesion requirements, particularly for dynamic applications or specialized substrates. Partnering with a manufacturer boasting extensive experience (e.g., 20+ years in the industry) and a diverse client portfolio (e.g., serving leading OEMs globally) adds a significant layer of confidence.

Application Case Studies & Customer Feedback (Experience)

Real-world application demonstrates the tangible benefits of high-quality sealing solutions:

Case Study 1: Industrial Bakery Oven Upgrade

- Challenge: A large industrial bakery faced significant heat loss and inconsistent baking temperatures due to deteriorating EPDM seals on their continuous tunnel ovens, leading to increased energy costs and product rejects. The existing seals degraded rapidly at continuous operating temperatures of 200°C.

- Solution: A specialized `window seal strip adhesive company` supplied custom-extruded E-shaped high-temperature silicone gaskets with a specific Shore A hardness (60A) to ensure optimal compression. The silicone's chemical inertness also resisted oils and greases common in the bakery environment.

- Result: Post-installation, the bakery reported a verifiable 18% reduction in energy consumption for the ovens within the first six months. Product consistency improved, reducing rejects by 7%, and the service life of the new silicone seals was projected to be 3-4 times longer than the previous EPDM seals, minimizing maintenance downtime.

Case Study 2: Cleanroom Equipment Manufacturer

- Challenge: A manufacturer of semiconductor processing equipment required ultra-clean, dust-free sealing for their access panels and doors to maintain ISO Class 5 cleanroom conditions. Standard rubber seals off-gassed VOCs and lacked sufficient compression set resistance.

- Solution: Working with a leading `window seal strip adhesive manufacturer`, they implemented specially formulated platinum-cured silicone P-shaped profiles, which are known for extremely low outgassing properties and superior resilience. The seals were provided with a medical-grade pressure-sensitive adhesive.

- Result: The client successfully met strict cleanroom particulate and VOC emission standards. Customer feedback highlighted the ease of installation and the long-term integrity of the seals, contributing to fewer contamination incidents and enhanced product yield for their end-users.

Trustworthiness & Customer Support

Frequently Asked Questions (FAQ):

A1: Under ideal operating conditions (within specified temperature limits, minimal chemical exposure, correct compression), a high-quality silicone seal can last 5-10 years or even longer. Factors like extreme cycling, abrasion, or harsh chemical exposure can shorten this. Reputable `window seal strip adhesive quotes` should reflect this long-term value.

A2: Absolutely. Most professional `window seal strip adhesive suppliers` offer extensive customization services, including custom tooling for unique profiles, specific lengths, various colors, and a range of durometers (hardness) to match precise application requirements. Engineering teams are typically available for consultation.

A3: For optimal adhesion, the application surface must be clean, dry, and free of grease or debris. Adhesion is typically best applied at room temperature. Proper compression should be considered to avoid over-compressing or under-compressing the seal, which can compromise its performance and service life.

Lead Time & Fulfillment:

Standard silicone seal strips generally have a lead time of 2-4 weeks, depending on order volume and specific product. Custom-engineered solutions requiring new tooling may extend to 6-8 weeks for initial prototype approval and subsequent production. Efficient supply chain management and global shipping capabilities ensure timely delivery for both domestic and international clients.

Warranty Commitments:

Reputable manufacturers typically offer a warranty against defects in material and workmanship for a period of 12-24 months from the date of purchase. This commitment underscores confidence in product quality and reliability, providing peace of mind to industrial clients.

Customer Support & Technical Assistance:

Comprehensive after-sales support is crucial. This includes dedicated technical support teams for installation guidance, troubleshooting, and material compatibility advice. Access to engineering consultation services ensures that clients receive expert assistance throughout the product lifecycle, from initial design to long-term maintenance.

Conclusion

The role of high-performance sealing strips, especially those engineered for challenging environments like oven doors, cannot be overstated in industrial applications. As demonstrated by the detailed specifications and real-world advantages of products from professional `window seal strip adhesive companies`, investing in superior sealing solutions translates directly into enhanced operational efficiency, reduced energy consumption, and extended equipment lifespan. The meticulous manufacturing processes, adherence to stringent quality standards, and emphasis on customization ensure that these critical components meet the ever-evolving demands of modern industry.

For B2B decision-makers and engineers, selecting a reliable partner among `window seal strip adhesive exporters` or manufacturers, one that offers robust technical support and a commitment to quality, is key to optimizing performance and achieving long-term value in their industrial systems.

References

- ASTM International. "D2000-12 Standard Classification System for Rubber Products in Automotive Applications."

- ISO. "ISO 3302-1:2014 Rubber -- Tolerances for products -- Part 1: Dimensional tolerances."

- Schnell, U. (2018). "Silicone Elastomers: Chemistry, Processing, and Applications." Smithers Rapra Technology.

- Kausch, H. H., & Ehrenstein, G. W. (2009). "Polymer Handbook." 4th Edition. Springer.

- Rubber Manufacturers Association (RMA). "Handbook of Molded, Extruded, Lathe Cut and Cellular Rubber Products."

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025