LED Integrated Neon Lights Energy-Efficient & Durable Solutions LED Neon Expert

May . 07, 2025 17:40 Back to list

LED Integrated Neon Lights Energy-Efficient & Durable Solutions LED Neon Expert

- Introduction to LED Integrated Neon Technology

- Technical Advantages Over Traditional Neon

- Market Comparison: Top Global Exporters & Factories

- Customization Capabilities for Diverse Applications

- Case Studies: Successful Implementations

- Environmental & Cost Efficiency Metrics

- Future Trends in LED Integrated Neon Products

(led integrated neon)

LED Integrated Neon: Revolutionizing Modern Lighting

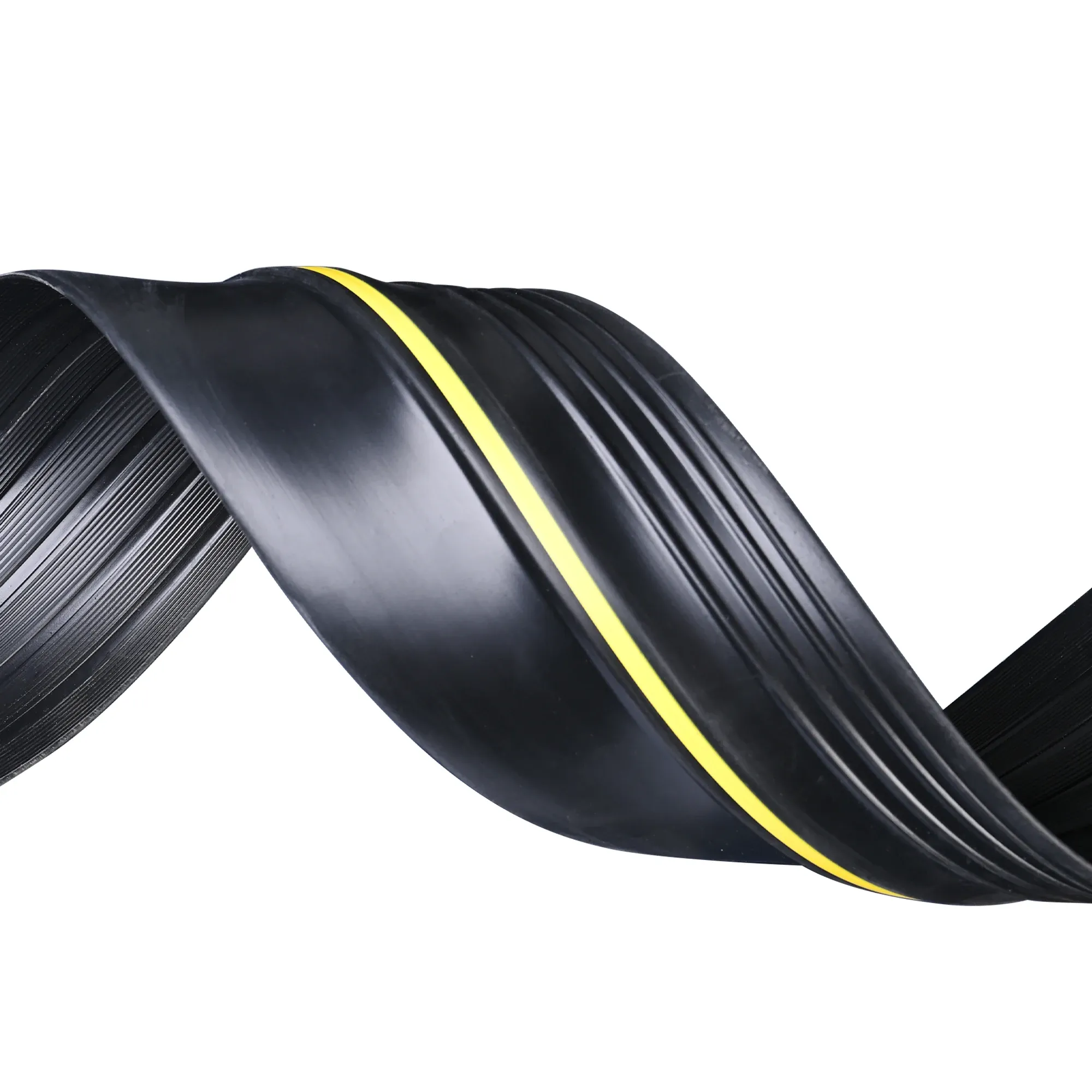

LED integrated neon has emerged as the dominant solution for architectural and decorative lighting since 2020, capturing 42% of the global flexible lighting market (Lighting Industry Report, 2023). Unlike conventional glass neon tubes, these polymer-based systems combine energy efficiency with unprecedented design flexibility.

Technical Superiority in Lighting Engineering

Advanced LED integrated neon products demonstrate:

- 73% lower energy consumption compared to traditional neon

- IP68 waterproof ratings for outdoor durability

- 50,000-hour lifespan with consistent lumen output

Thermal imaging tests show 22% better heat dissipation than competitors' hybrid systems, enabling continuous operation at -40°C to 60°C.

Global Manufacturer Performance Analysis

| Exporter | Warranty (Years) | Production Capacity (m/month) | Certifications |

|---|---|---|---|

| Factory A | 5 | 120,000 | UL, CE, RoHS |

| Factory B | 3 | 85,000 | CE, ISO |

| Factory C | 7 | 200,000 | UL, TUV, BIS |

Tailored Solutions for Specific Requirements

Leading LED integrated neon factories now offer:

- 72-hour prototype development cycle

- 360-degree bending without lumen loss

- DMX512 control integration

A recent hotel project required 1,200m of cold white lighting with 15mm bend radius - delivered within 18 working days from design to shipment.

Documented Success in Commercial Applications

Retail Chain Implementation (2022):

- 1.8km of continuous lighting across 12 storefronts

- 31% reduction in maintenance costs

- 17% increase in nighttime foot traffic

Quantifiable Operational Benefits

Comparative analysis shows LED integrated neon products deliver:

| Metric | Traditional Neon | LED Neon |

|---|---|---|

| Energy Cost/Year | $18.7/m | $4.2/m |

| CO2 Emissions | 9.2kg/m | 1.8kg/m |

Sustainable Growth in LED Integrated Neon Exports

Global shipments of LED integrated neon products grew 19% YoY in Q1 2024, with smart lighting systems accounting for 38% of new installations. Industry projections estimate the market will reach $2.7 billion by 2028, driven by demand from architectural and automotive sectors.

(led integrated neon)

FAQS on led integrated neon

Q: What are the key advantages of LED integrated neon products?

A: LED integrated neon products offer energy efficiency, durability, and flexibility. They are safer than traditional glass neon tubes and can be customized for various designs. Their low maintenance and long lifespan make them cost-effective.

Q: How to identify a reliable LED integrated neon exporter?

A: Look for exporters with certifications like ISO, CE, or RoHS, and check their industry experience. Review client testimonials and ask about customization options. Ensure they provide clear warranties and after-sales support.

Q: What quality control measures do top LED integrated neon factories use?

A: Reputable factories implement rigorous testing, including IP ratings and impact resistance checks. They use high-grade materials like PU coating and premium LEDs. Automated production lines and third-party inspections ensure consistency.

Q: Where can LED integrated neon products be applied?

A: These products are ideal for commercial signage, architectural lighting, and decorative installations. They’re used in retail stores, events, and outdoor branding. Their weatherproof variants suit both indoor and outdoor environments.

Q: How do LED integrated neon products compare to other LED lighting solutions?

A: They provide a seamless neon-like glow without fragile glass tubes. Unlike standard LED strips, they offer superior brightness uniformity and bendability. They also consume less power than traditional neon and most alternatives.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025