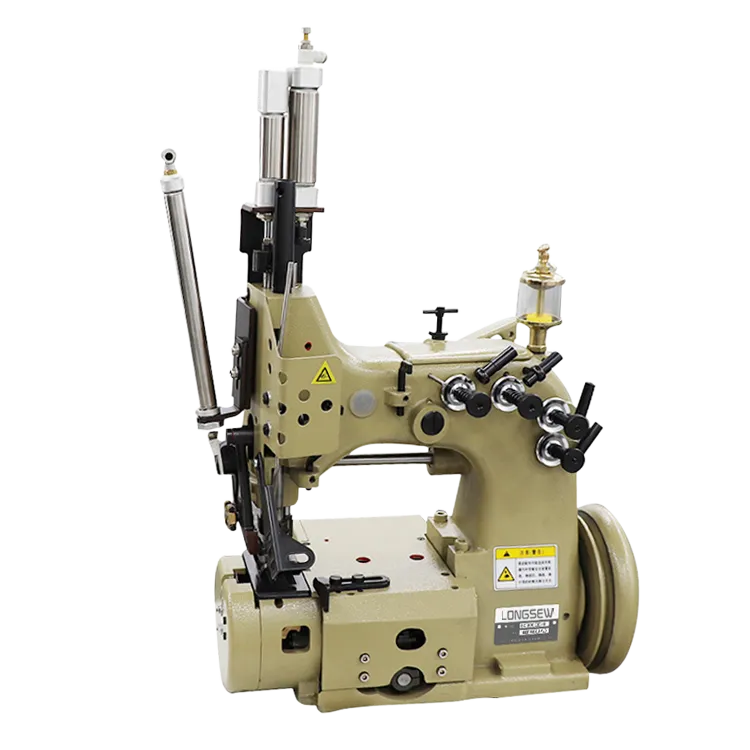

In summary, the industrial chain stitch machine is an indispensable tool in textile manufacturing. Its unique stitching mechanism, combined with advantages like speed, durability, and cost-effectiveness, positions it as a preferred option for many manufacturers. As the textile industry continues to evolve, innovations in chain stitch technology are likely to enhance its capabilities further, solidifying its status as a key player in the production of high-quality garments and textiles. As manufacturers seek to balance efficiency with quality, the industrial chain stitch machine remains a cornerstone of successful apparel production strategies.

Home

Home