In conclusion, DS Brown's strip seal products are an essential component for any construction or infrastructure project that requires reliable sealing solutions. Their combination of durability, design flexibility, ease of installation, and cost-effectiveness make them a top choice for engineers and contractors alike. As infrastructure continues to age and require upgrades, the role of high-quality materials like those offered by DS Brown will become increasingly crucial in ensuring safety and longevity. Investing in DS Brown strip seal products is not just a choice; it’s a commitment to excellence in construction.

Home

Home

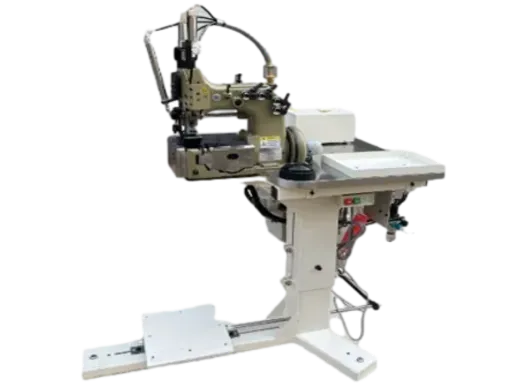

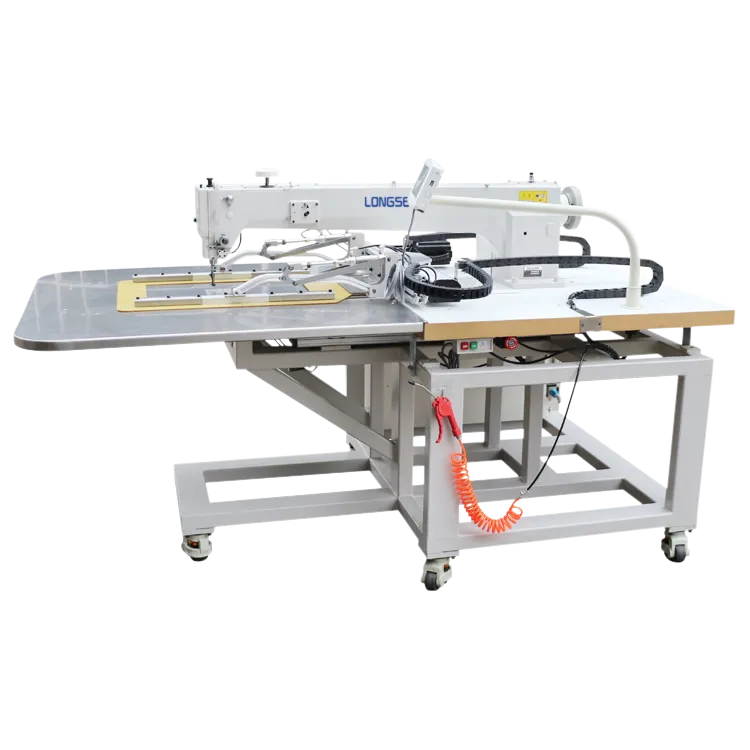

The durability and strength of these stitches are crucial, as they ensure the sail can withstand the relentless pull of wind and waves The durability and strength of these stitches are crucial, as they ensure the sail can withstand the relentless pull of wind and waves

The durability and strength of these stitches are crucial, as they ensure the sail can withstand the relentless pull of wind and waves The durability and strength of these stitches are crucial, as they ensure the sail can withstand the relentless pull of wind and waves