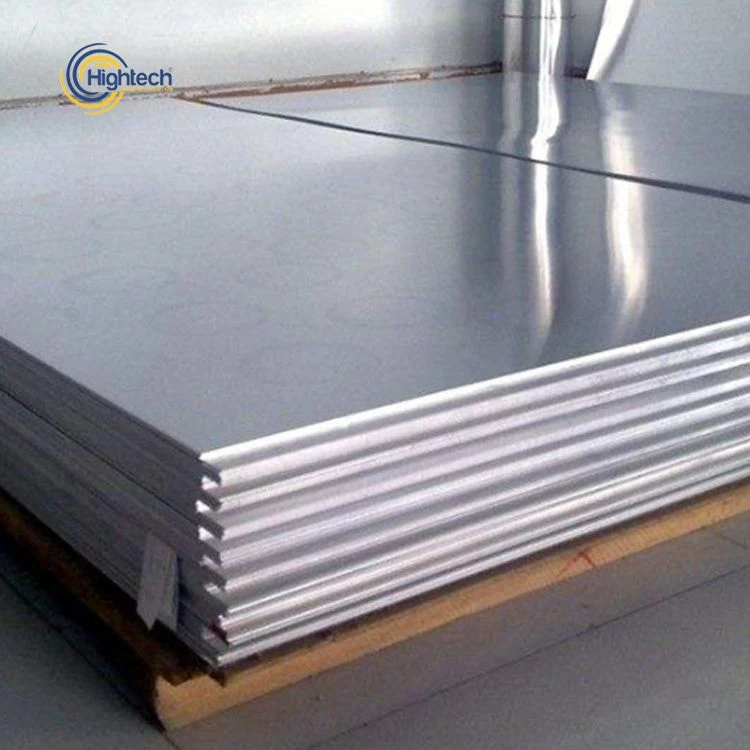

stainless steel pricelist

Home

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

%20(200%20%C3%97%20200%20px)%20(2)%20(1).webp)