stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

**Storage** Store floor line tape in a dry, cool place to prevent it from becoming brittle or losing its adhesiveness **Storage** Store floor line tape in a dry, cool place to prevent it from becoming brittle or losing its adhesiveness

**Storage** Store floor line tape in a dry, cool place to prevent it from becoming brittle or losing its adhesiveness **Storage** Store floor line tape in a dry, cool place to prevent it from becoming brittle or losing its adhesiveness

The wrap helps to keep the wires in place and organized, ensuring that the car's electrical system functions properly The wrap helps to keep the wires in place and organized, ensuring that the car's electrical system functions properly

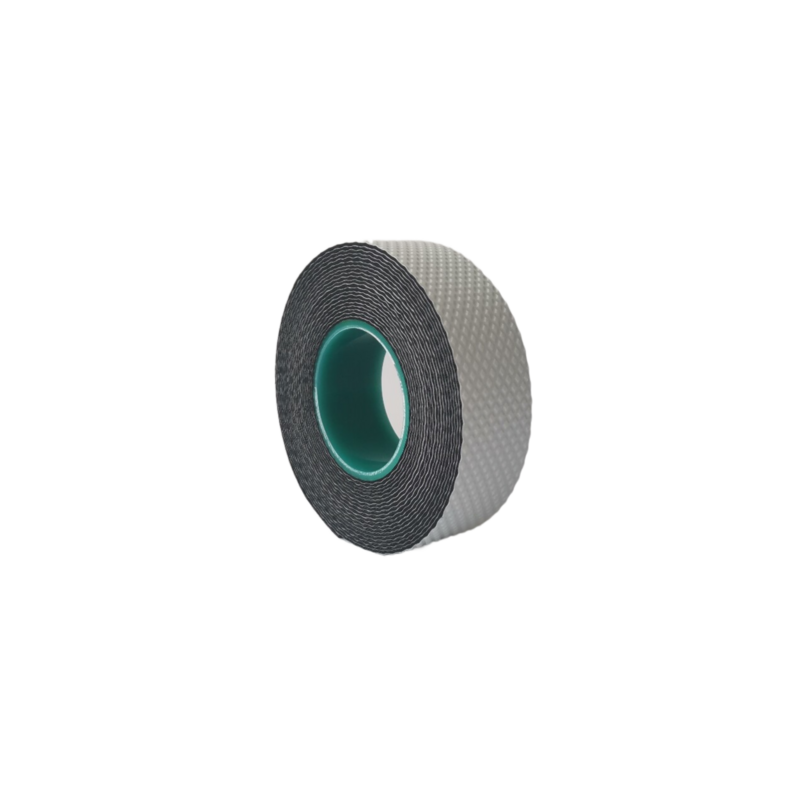

The wrap helps to keep the wires in place and organized, ensuring that the car's electrical system functions properly The wrap helps to keep the wires in place and organized, ensuring that the car's electrical system functions properly Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications

Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications