stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

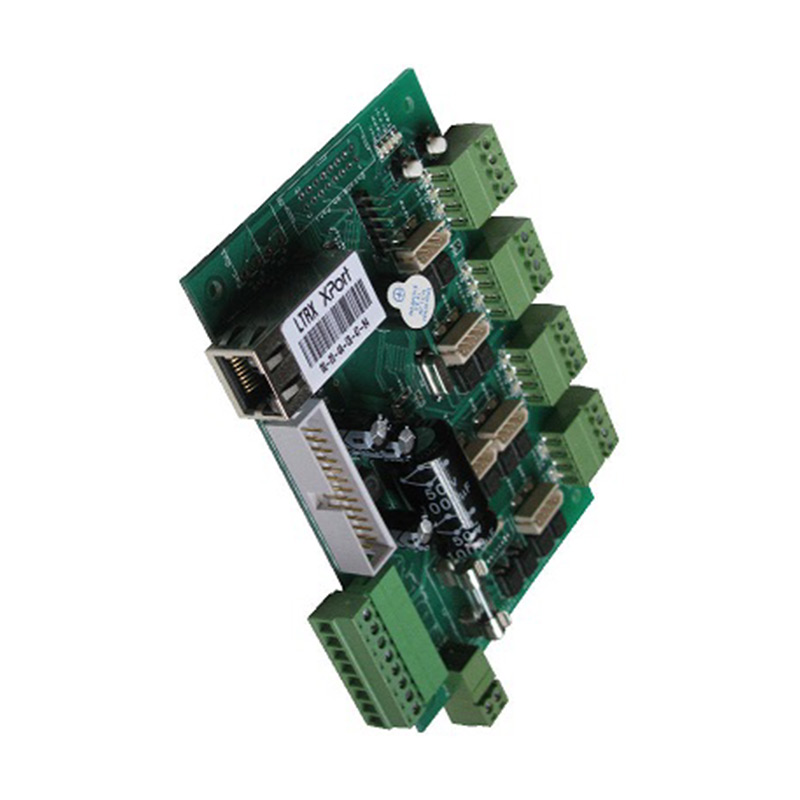

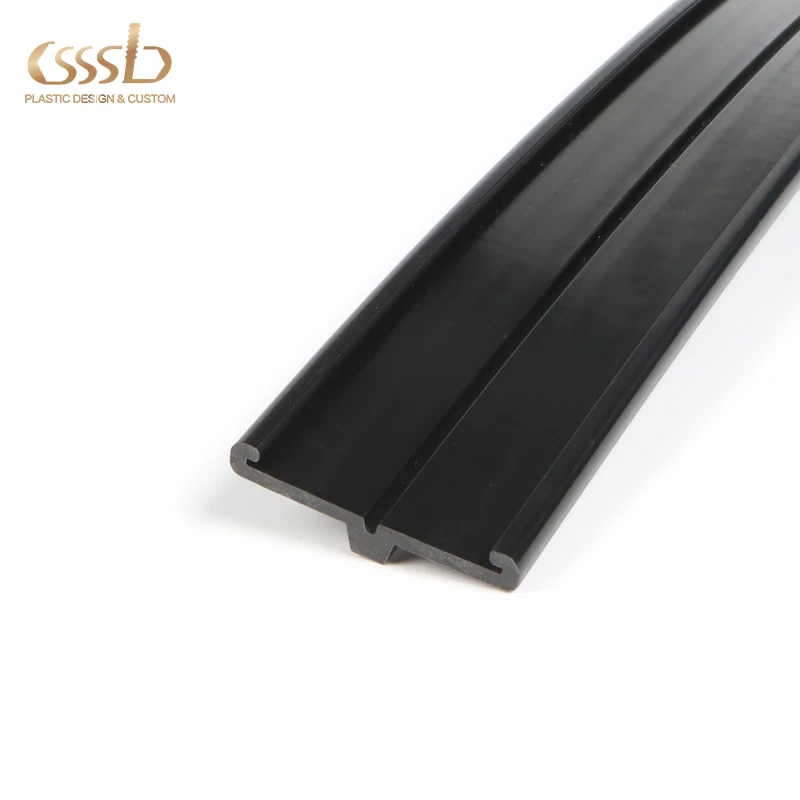

It can be used in a wide range of applications, including residential and commercial construction, automotive industry, and electronics It can be used in a wide range of applications, including residential and commercial construction, automotive industry, and electronics

It can be used in a wide range of applications, including residential and commercial construction, automotive industry, and electronics It can be used in a wide range of applications, including residential and commercial construction, automotive industry, and electronics