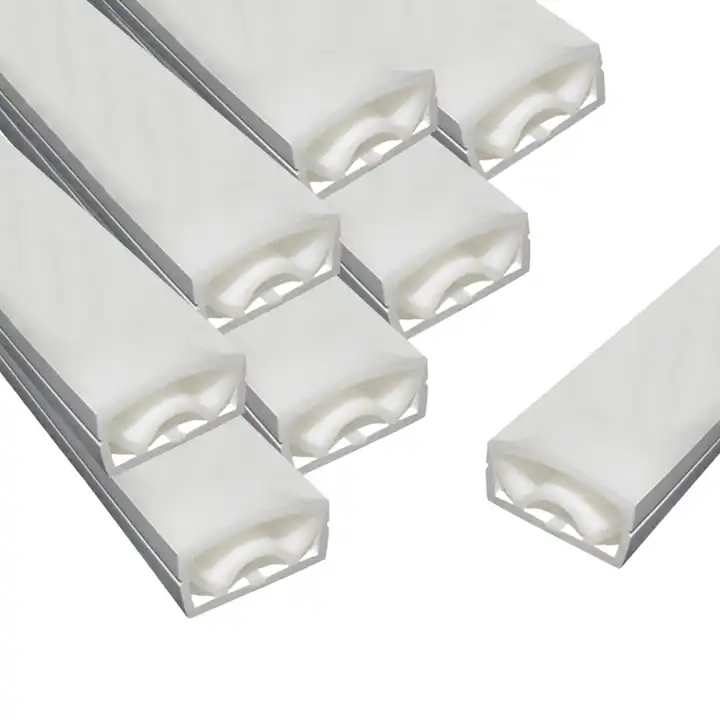

PVC, or polyvinyl chloride, is a budget-friendly option that is becoming increasingly popular for channel letters. It is lightweight and easily cut into various shapes, making it a versatile choice for custom designs. PVC is also resistant to moisture and is less likely to fade compared to other materials. However, it may not be as durable as metal options and can be more susceptible to damage from impacts or extreme temperatures. Therefore, while PVC channel letters can be a cost-effective solution, businesses should consider their specific needs and environmental factors before opting for this material.

Home

Home

Here are the steps to follow

Here are the steps to follow