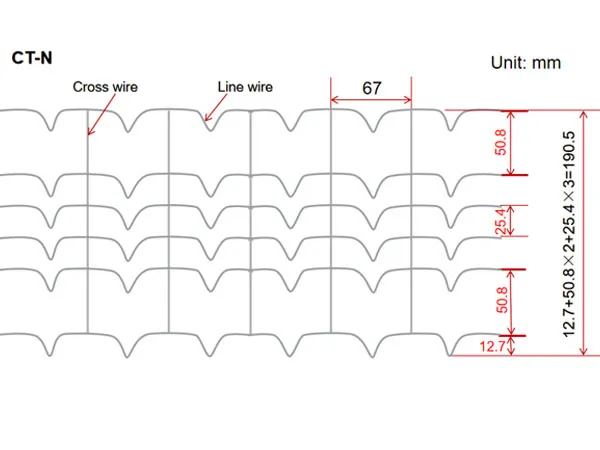

Steel grating is used to cover a portion of the structure and flooring that requires for instance light, liquid, air, heat, and sound to pass through. It is an ideal choice for projects ranging from trenches and stair treads to decking and steel flooring. Although not completely covered, steel grating is strong enough to support loads such as humans. Since the plates are positioned in a manner that can increase their strength. However, they are not suitable to resist bearing load from the structures and should not be used as a frame, beam, or column.

Home

Home