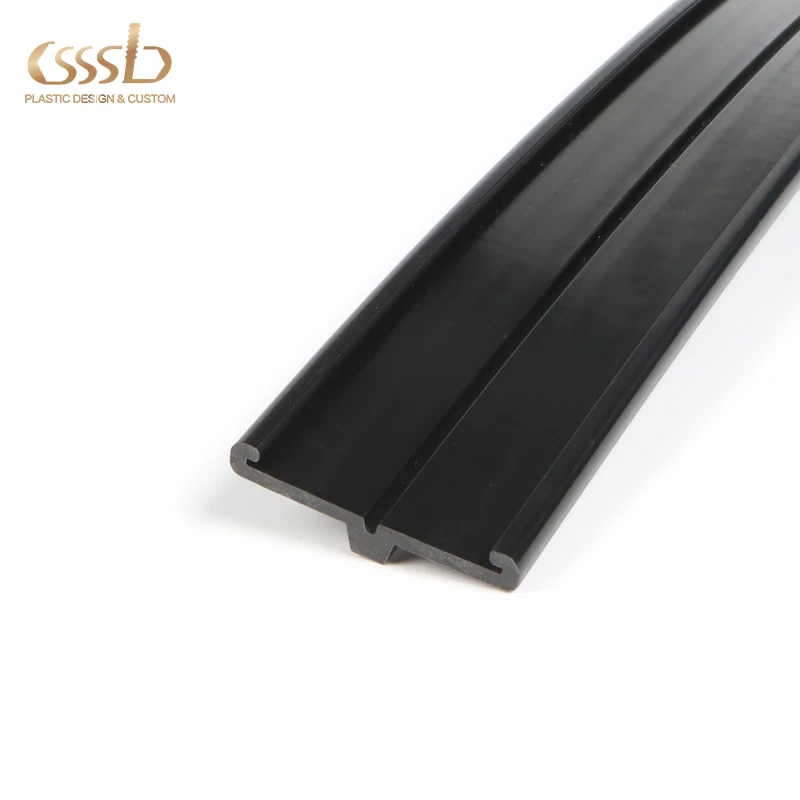

In today's competitive market, the demand for well-designed, efficient, and durable products has never been higher. Glass doors have become increasingly popular in commercial and residential spaces for their sleek aesthetic and ability to provide natural light. However, one often-overlooked component of these glass doors is the side seal strip, which plays a crucial role in ensuring energy efficiency, noise reduction, and overall functionality. This article delves into the significance of glass door side seal strip manufacturers, exploring their vital role in ensuring quality and performance in glass door installations.

Home

Home

The head is formed at one end, while the other end is cut and shaped into a sharp point The head is formed at one end, while the other end is cut and shaped into a sharp point

The head is formed at one end, while the other end is cut and shaped into a sharp point The head is formed at one end, while the other end is cut and shaped into a sharp point They also required fewer nails per unit area, making them more cost-effective in large-scale shipbuilding projects They also required fewer nails per unit area, making them more cost-effective in large-scale shipbuilding projects

They also required fewer nails per unit area, making them more cost-effective in large-scale shipbuilding projects They also required fewer nails per unit area, making them more cost-effective in large-scale shipbuilding projects