In conclusion, CE certification is an indispensable aspect of manufacturing LED split neon products for the European market. It not only ensures safety and quality but also facilitates trade and builds consumer trust. For manufacturers, understanding and navigating the CE certification process can be complex, but it is crucial for successfully entering the European market. As the demand for innovative and efficient lighting solutions continues to grow, adhering to these standards will ensure that products meet the expectations of safety, quality, and performance that consumers rightly demand.

Home

Home

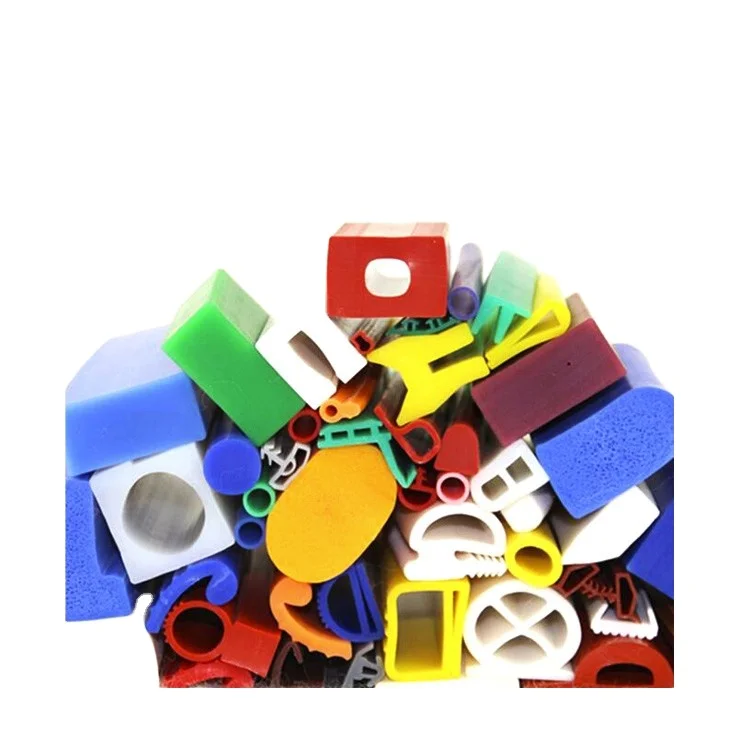

This makes it ideal for use in high-performance machinery and automotive systems where reliability is paramount This makes it ideal for use in high-performance machinery and automotive systems where reliability is paramount

This makes it ideal for use in high-performance machinery and automotive systems where reliability is paramount This makes it ideal for use in high-performance machinery and automotive systems where reliability is paramount