stainless steel pricelist

Home

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

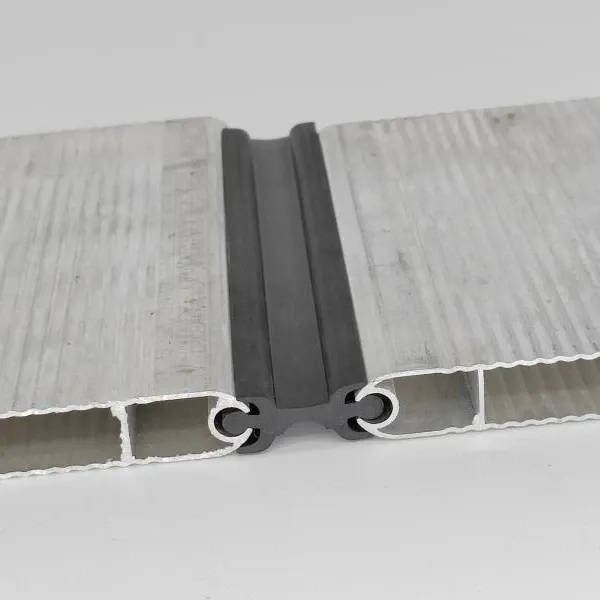

Made from high-quality materials such as brass, stainless steel, and aluminum, they are built to withstand the rigors of daily use Made from high-quality materials such as brass, stainless steel, and aluminum, they are built to withstand the rigors of daily use

Made from high-quality materials such as brass, stainless steel, and aluminum, they are built to withstand the rigors of daily use Made from high-quality materials such as brass, stainless steel, and aluminum, they are built to withstand the rigors of daily use

The size of the handle can also be customized, from compact options for drawers to longer pulls for cabinet doors, ensuring a cohesive look across different furniture pieces The size of the handle can also be customized, from compact options for drawers to longer pulls for cabinet doors, ensuring a cohesive look across different furniture pieces

The size of the handle can also be customized, from compact options for drawers to longer pulls for cabinet doors, ensuring a cohesive look across different furniture pieces The size of the handle can also be customized, from compact options for drawers to longer pulls for cabinet doors, ensuring a cohesive look across different furniture pieces