stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

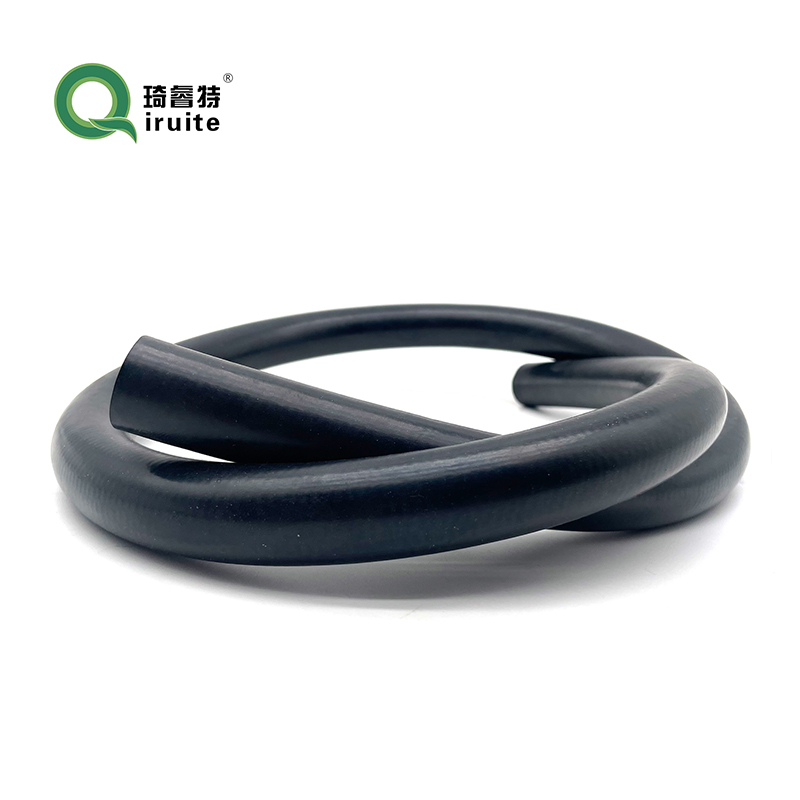

Regular maintenance and timely checks of the power steering hose are crucial to prevent such issues and maintain optimal performance Regular maintenance and timely checks of the power steering hose are crucial to prevent such issues and maintain optimal performance

Regular maintenance and timely checks of the power steering hose are crucial to prevent such issues and maintain optimal performance Regular maintenance and timely checks of the power steering hose are crucial to prevent such issues and maintain optimal performance Look for cracks, tears, or discoloration, which can indicate that the o-ring needs to be replaced Look for cracks, tears, or discoloration, which can indicate that the o-ring needs to be replaced

Look for cracks, tears, or discoloration, which can indicate that the o-ring needs to be replaced Look for cracks, tears, or discoloration, which can indicate that the o-ring needs to be replaced

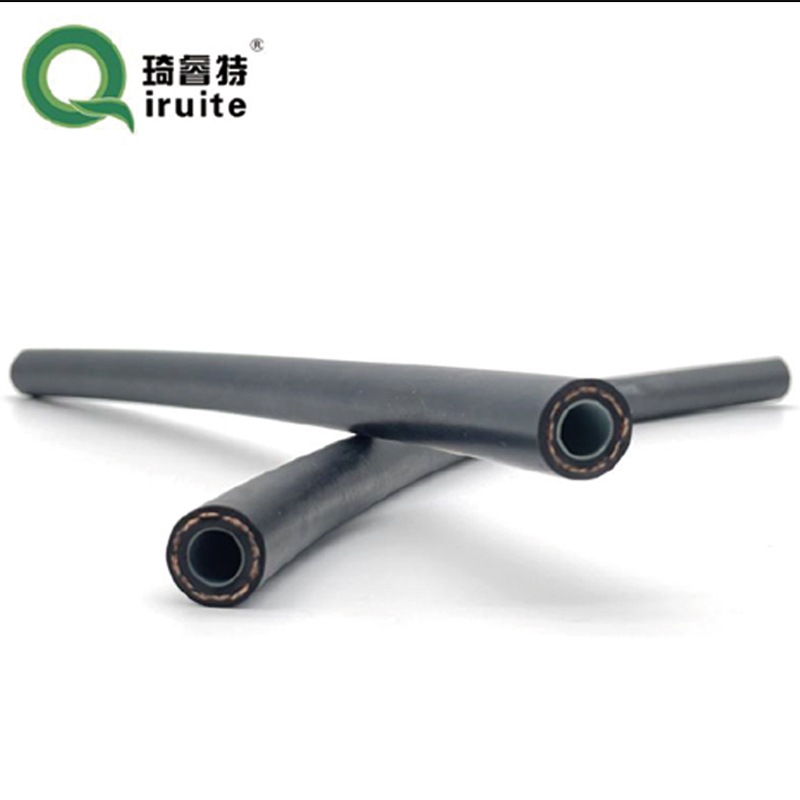

They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer

They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer