stainless steel pricelist

Home

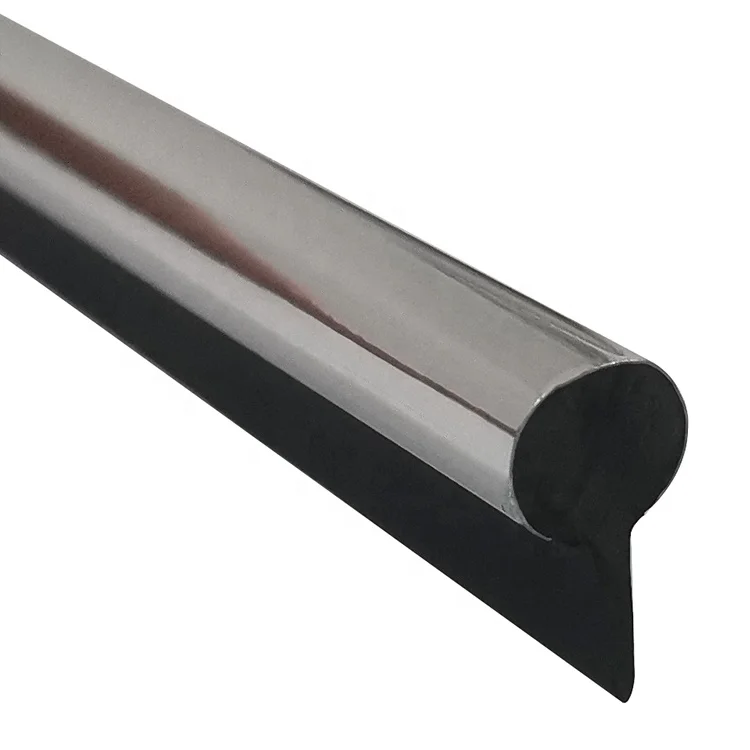

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

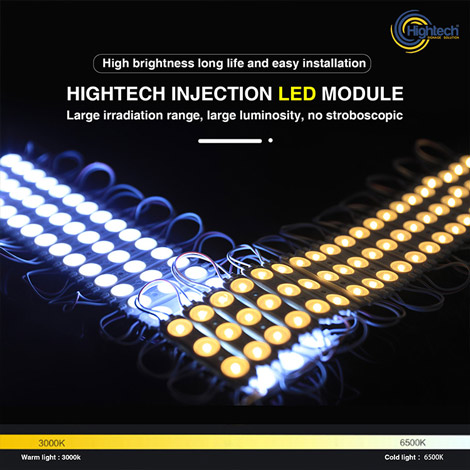

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

These seals are typically made from rubber or polyurethane materials and are designed to withstand high pressures and temperatures These seals are typically made from rubber or polyurethane materials and are designed to withstand high pressures and temperatures

These seals are typically made from rubber or polyurethane materials and are designed to withstand high pressures and temperatures These seals are typically made from rubber or polyurethane materials and are designed to withstand high pressures and temperatures

By maintaining optimal oil viscosity, the TCV helps to reduce friction between the engine's moving parts, resulting in increased fuel efficiency and reduced wear and tear on the engine By maintaining optimal oil viscosity, the TCV helps to reduce friction between the engine's moving parts, resulting in increased fuel efficiency and reduced wear and tear on the engine

By maintaining optimal oil viscosity, the TCV helps to reduce friction between the engine's moving parts, resulting in increased fuel efficiency and reduced wear and tear on the engine By maintaining optimal oil viscosity, the TCV helps to reduce friction between the engine's moving parts, resulting in increased fuel efficiency and reduced wear and tear on the engine