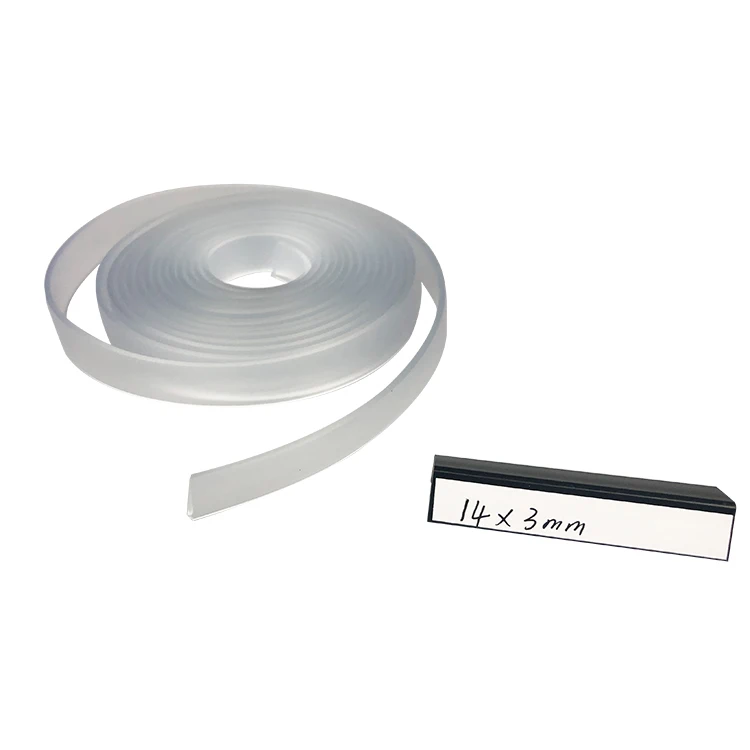

Door bottom seal rubber strips are essential components in modern construction, providing a myriad of benefits that enhance both the functionality and efficiency of doors. These strips are primarily used to seal the gap between the bottom of a door and the floor, ensuring the space is insulated against drafts, dust, moisture, and pests. Given the significance of these seals, numerous factories around the world specialize in their production, employing advanced manufacturing processes to deliver high-quality products to consumers.

Home

Home

They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance

They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance They ensure precise control over the air-fuel mixture, leading to better fuel economy, reduced emissions, and improved overall performance