stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

. Their surfaces, at once opaque and transparent, challenge our perception of space and volume. These buildings not only house functions but also invigorate urban landscapes with their dynamic interaction with the surroundings.

. Their surfaces, at once opaque and transparent, challenge our perception of space and volume. These buildings not only house functions but also invigorate urban landscapes with their dynamic interaction with the surroundings. These cracks are not signs of defeat but evidence of the trials we've weathered These cracks are not signs of defeat but evidence of the trials we've weathered

These cracks are not signs of defeat but evidence of the trials we've weathered These cracks are not signs of defeat but evidence of the trials we've weathered

The metallic gleam of silver can effortlessly blend into both traditional and contemporary decors, making it a versatile choice The metallic gleam of silver can effortlessly blend into both traditional and contemporary decors, making it a versatile choice

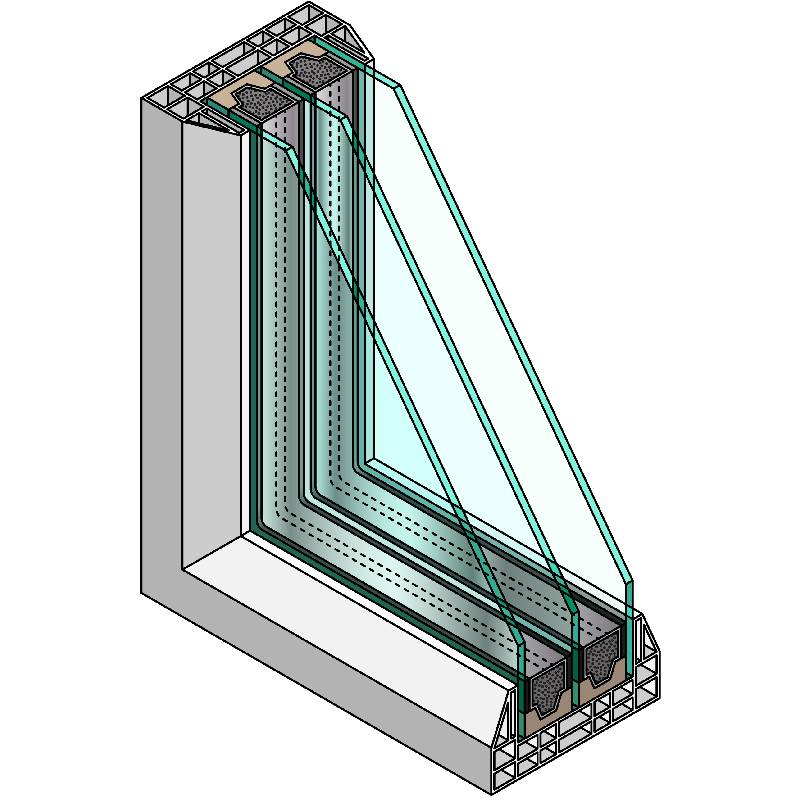

The metallic gleam of silver can effortlessly blend into both traditional and contemporary decors, making it a versatile choice The metallic gleam of silver can effortlessly blend into both traditional and contemporary decors, making it a versatile choice Furthermore, side windows and sunroofs often use laminated glass, which includes a layer of tempered glass sandwiched between sheets of plastic for added protection Furthermore, side windows and sunroofs often use laminated glass, which includes a layer of tempered glass sandwiched between sheets of plastic for added protection

Furthermore, side windows and sunroofs often use laminated glass, which includes a layer of tempered glass sandwiched between sheets of plastic for added protection Furthermore, side windows and sunroofs often use laminated glass, which includes a layer of tempered glass sandwiched between sheets of plastic for added protection