stainless steel pricelist

Home

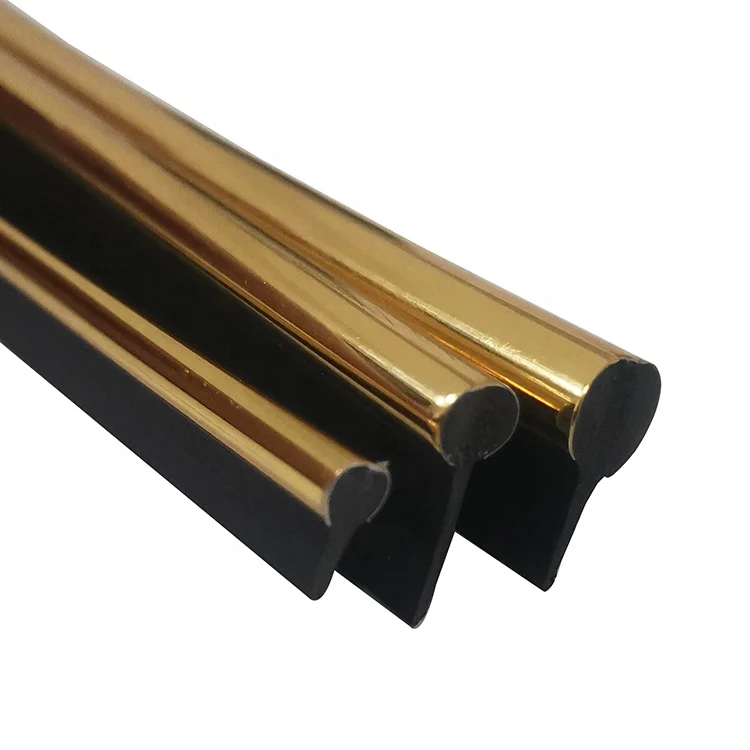

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

Without sufficient iron, plants cannot take up nutrients properly, leading to nutrient deficiencies and reduced growth Without sufficient iron, plants cannot take up nutrients properly, leading to nutrient deficiencies and reduced growth

Without sufficient iron, plants cannot take up nutrients properly, leading to nutrient deficiencies and reduced growth Without sufficient iron, plants cannot take up nutrients properly, leading to nutrient deficiencies and reduced growth This modular approach aligns well with the principles of modern construction, which favor speed, consistency, and industrialization This modular approach aligns well with the principles of modern construction, which favor speed, consistency, and industrialization

This modular approach aligns well with the principles of modern construction, which favor speed, consistency, and industrialization This modular approach aligns well with the principles of modern construction, which favor speed, consistency, and industrialization

It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens

It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens They understand the nuances of the construction process and can advise on the optimal mesh configuration for a given project, taking into account factors such as soil conditions, expected loads, and environmental factors They understand the nuances of the construction process and can advise on the optimal mesh configuration for a given project, taking into account factors such as soil conditions, expected loads, and environmental factors

They understand the nuances of the construction process and can advise on the optimal mesh configuration for a given project, taking into account factors such as soil conditions, expected loads, and environmental factors They understand the nuances of the construction process and can advise on the optimal mesh configuration for a given project, taking into account factors such as soil conditions, expected loads, and environmental factors