stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

For instance, recycled plastic or composite fencing might be a more eco-friendly choice despite potentially higher upfront costs For instance, recycled plastic or composite fencing might be a more eco-friendly choice despite potentially higher upfront costs

For instance, recycled plastic or composite fencing might be a more eco-friendly choice despite potentially higher upfront costs For instance, recycled plastic or composite fencing might be a more eco-friendly choice despite potentially higher upfront costs

Their open structure allows light and air passage, making them suitable for decorative facades, balustrades, and window guards Their open structure allows light and air passage, making them suitable for decorative facades, balustrades, and window guards

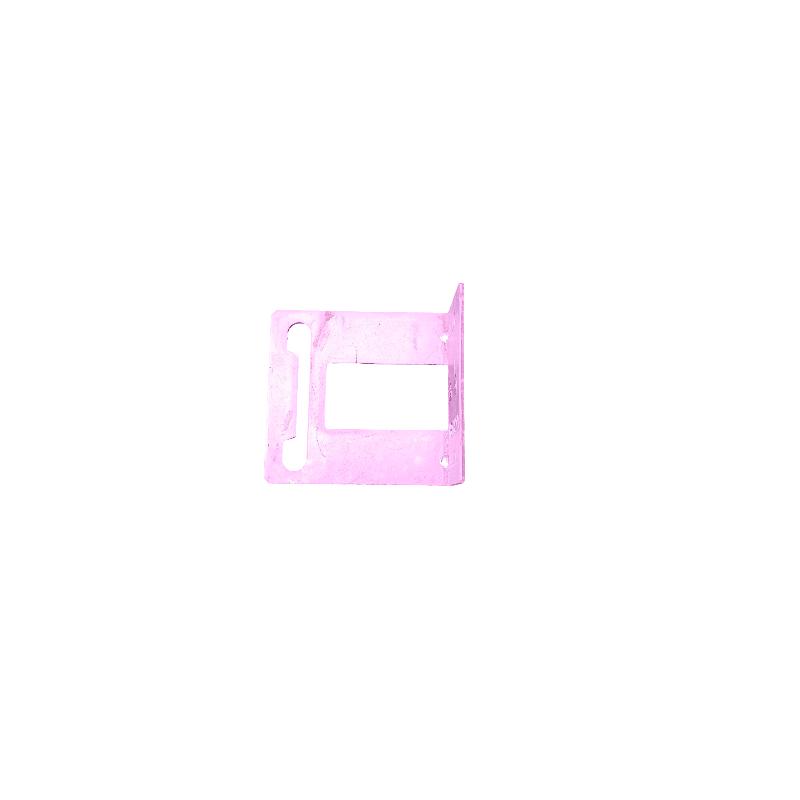

Their open structure allows light and air passage, making them suitable for decorative facades, balustrades, and window guards Their open structure allows light and air passage, making them suitable for decorative facades, balustrades, and window guards Engineers and architects often collaborate to determine the most appropriate anchor design, ensuring compliance with local building codes and standards Engineers and architects often collaborate to determine the most appropriate anchor design, ensuring compliance with local building codes and standards

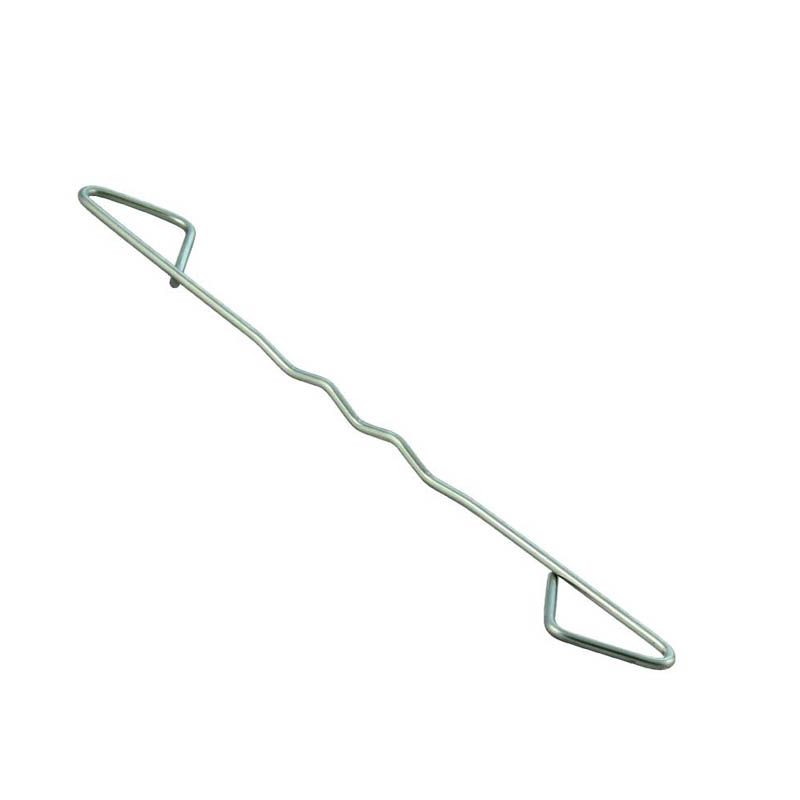

Engineers and architects often collaborate to determine the most appropriate anchor design, ensuring compliance with local building codes and standards Engineers and architects often collaborate to determine the most appropriate anchor design, ensuring compliance with local building codes and standards 2mm garden wire can also be used for a variety of other tasks in the garden2mm garden wire can also be used for a variety of other tasks in the garden

2mm garden wire can also be used for a variety of other tasks in the garden2mm garden wire can also be used for a variety of other tasks in the garden The choice of material, usually steel, stainless steel, or alloy, influences the spring's strength, corrosion resistance, and temperature tolerance The choice of material, usually steel, stainless steel, or alloy, influences the spring's strength, corrosion resistance, and temperature tolerance

The choice of material, usually steel, stainless steel, or alloy, influences the spring's strength, corrosion resistance, and temperature tolerance The choice of material, usually steel, stainless steel, or alloy, influences the spring's strength, corrosion resistance, and temperature tolerance