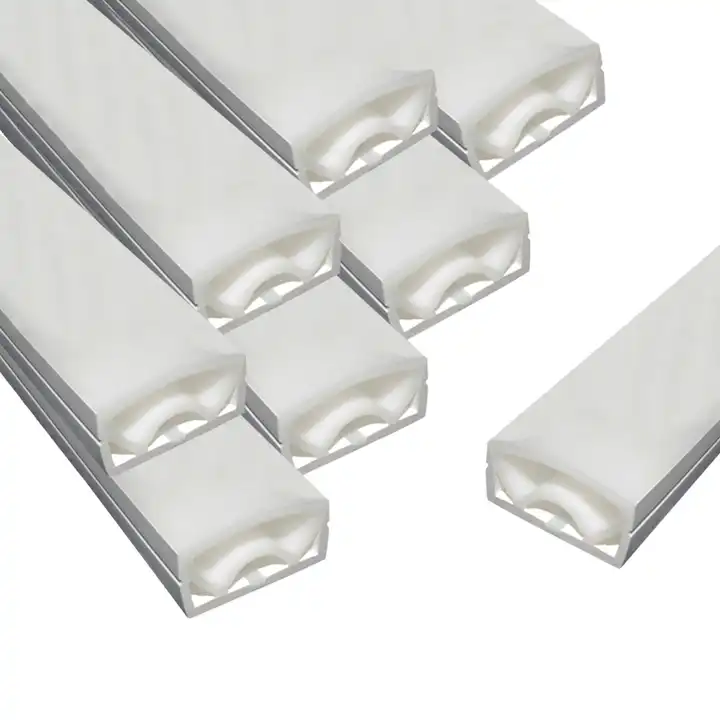

Double glazing door seal strips are specialized components used to create a tight seal between the door and its frame, preventing drafts, moisture, and noise from entering the home. Typically made from materials such as rubber, silicone, or foam, these strips are engineered to withstand varying environmental conditions while maintaining their shape and effectiveness over time. The primary function of these seals is to enhance thermal insulation, making heating and cooling systems more effective and reducing energy costs.

Home

Home