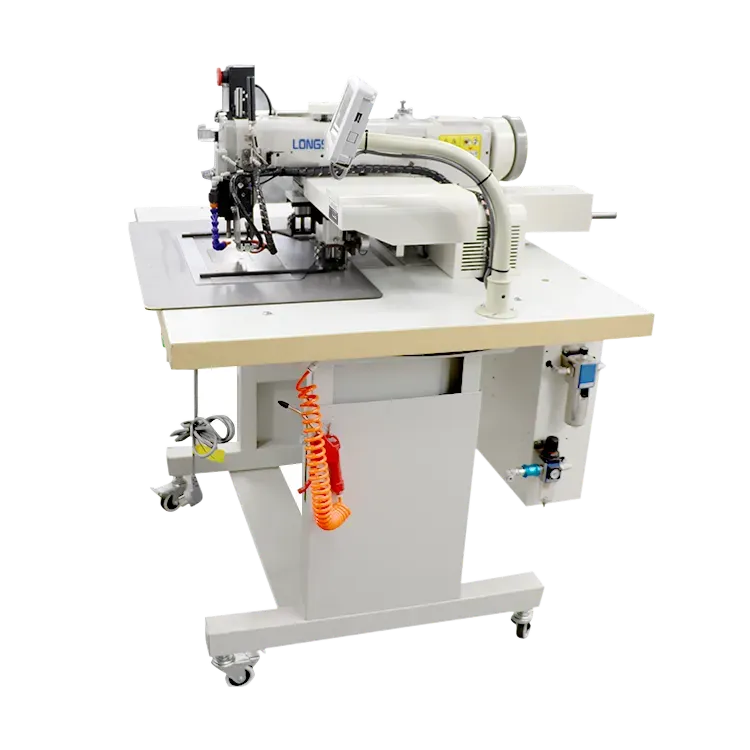

In conclusion, industrial overlock sewing machines play a vital role in the textile industry. Their ability to deliver high-speed, quality stitching while ensuring durability makes them essential for garment manufacturers. As the fashion industry continues to evolve, the relevance of these machines is only set to increase. For businesses aiming to stay competitive in a fast-paced market, investing in advanced overlock sewing technology is a strategic move that can lead to better productivity, superior quality, and ultimately, greater profitability. The journey of fabric transformation from raw material to finished garment is significantly streamlined by the capabilities of industrial overlock sewing machines, highlighting their importance in the modern textile landscape.

Home

Home