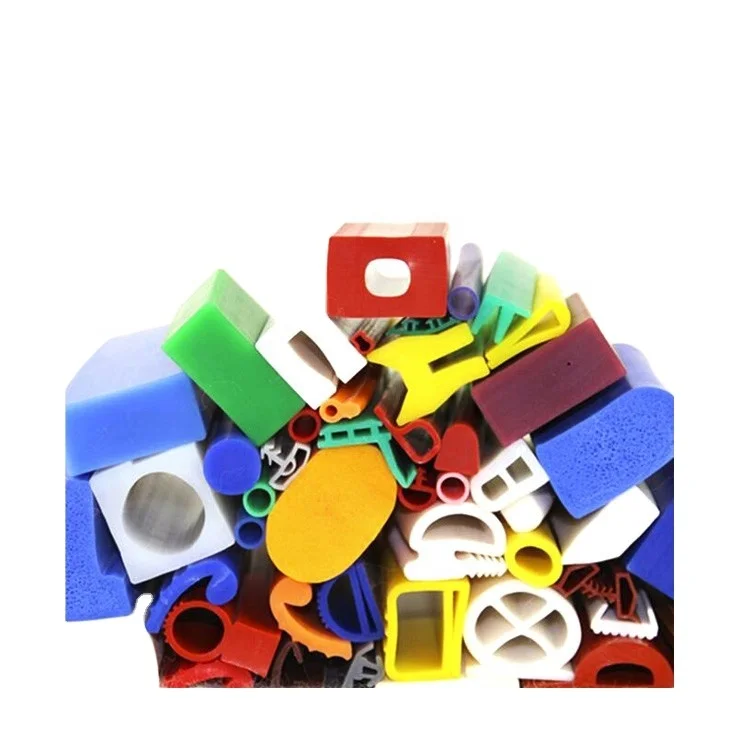

Investing in waterproof seal strips is a smart choice for homeowners looking to enhance the durability and efficiency of their living spaces. Understanding the various factors that influence price can help you make an informed purchase. Whether you are tackling a small DIY project or conducting a major renovation, choosing the right seal strips will provide peace of mind, knowing that your home is protected from moisture intrusion while also preserving its energy efficiency. Take the time to explore different options, compare prices, and select the best waterproof seal strips for your needs. Your home will thank you!

Home

Home

By prioritizing sustainability, we aim to contribute to a cleaner, greener future for our planet By prioritizing sustainability, we aim to contribute to a cleaner, greener future for our planet

By prioritizing sustainability, we aim to contribute to a cleaner, greener future for our planet By prioritizing sustainability, we aim to contribute to a cleaner, greener future for our planet