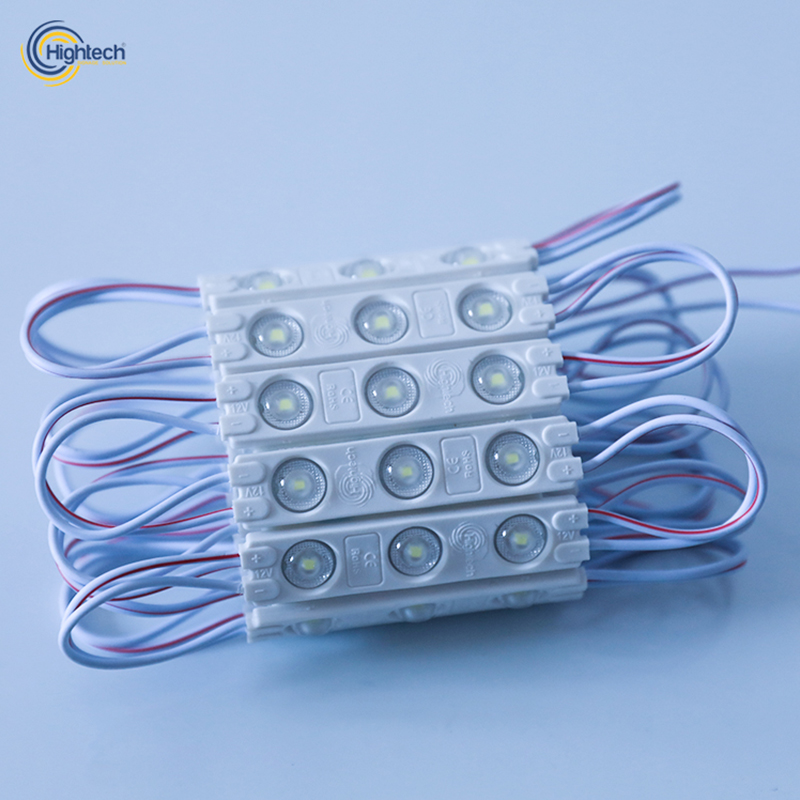

Silica gel LED strip suppliers play a crucial role in the advancement of modern lighting solutions. With their unique properties, silica gel encased strips provide safe, durable, and aesthetically pleasing lighting options for various applications. When looking for a supplier, it's essential to consider factors such as quality, variety, support, pricing, and reputation. By making informed choices, customers can illuminate their spaces with stylish and practical lighting solutions, enhancing environment and functionality alike. As the popularity of LED lighting continues to grow, the importance of selecting the right supplier remains paramount in achieving desired outcomes in lighting design.

Home

Home

In electric motors, it supports the rotor's rotation with precision, enhancing overall performance In electric motors, it supports the rotor's rotation with precision, enhancing overall performance

In electric motors, it supports the rotor's rotation with precision, enhancing overall performance In electric motors, it supports the rotor's rotation with precision, enhancing overall performance