stainless steel pricelist

Home

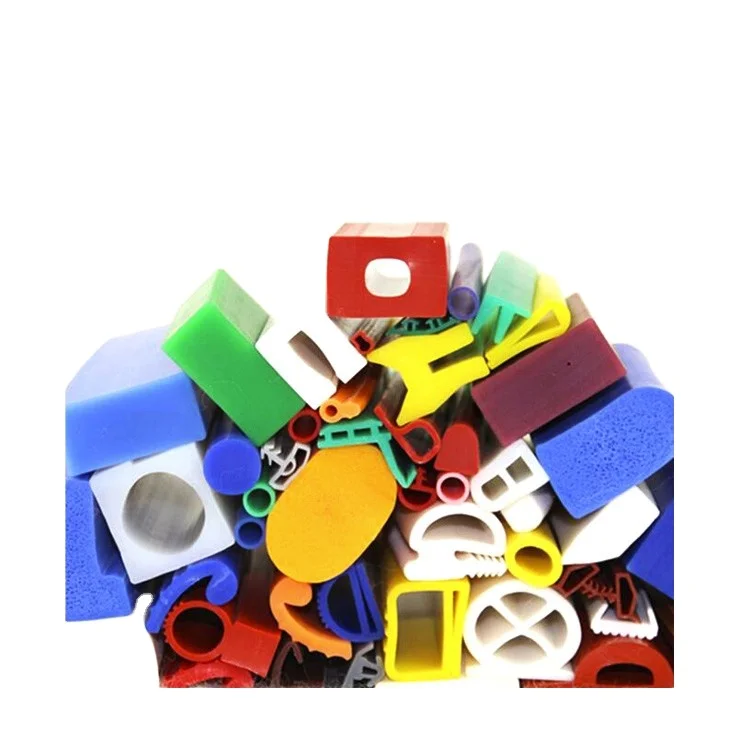

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

Furthermore, their open-grid design promotes good visibility, preventing trip hazards and allowing for easy monitoring of the area beneath the walkway Furthermore, their open-grid design promotes good visibility, preventing trip hazards and allowing for easy monitoring of the area beneath the walkway

Furthermore, their open-grid design promotes good visibility, preventing trip hazards and allowing for easy monitoring of the area beneath the walkway Furthermore, their open-grid design promotes good visibility, preventing trip hazards and allowing for easy monitoring of the area beneath the walkway

Additionally, its durability ensures that it can withstand heavy-duty use without bending or breaking Additionally, its durability ensures that it can withstand heavy-duty use without bending or breaking

Additionally, its durability ensures that it can withstand heavy-duty use without bending or breaking Additionally, its durability ensures that it can withstand heavy-duty use without bending or breaking This is particularly useful when working on projects that require drilling through walls or reaching into tight spaces This is particularly useful when working on projects that require drilling through walls or reaching into tight spaces

This is particularly useful when working on projects that require drilling through walls or reaching into tight spaces This is particularly useful when working on projects that require drilling through walls or reaching into tight spaces

Compared to traditional steel or concrete tanks, GRP tanks are significantly lighter Compared to traditional steel or concrete tanks, GRP tanks are significantly lighter

Compared to traditional steel or concrete tanks, GRP tanks are significantly lighter Compared to traditional steel or concrete tanks, GRP tanks are significantly lighter