stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

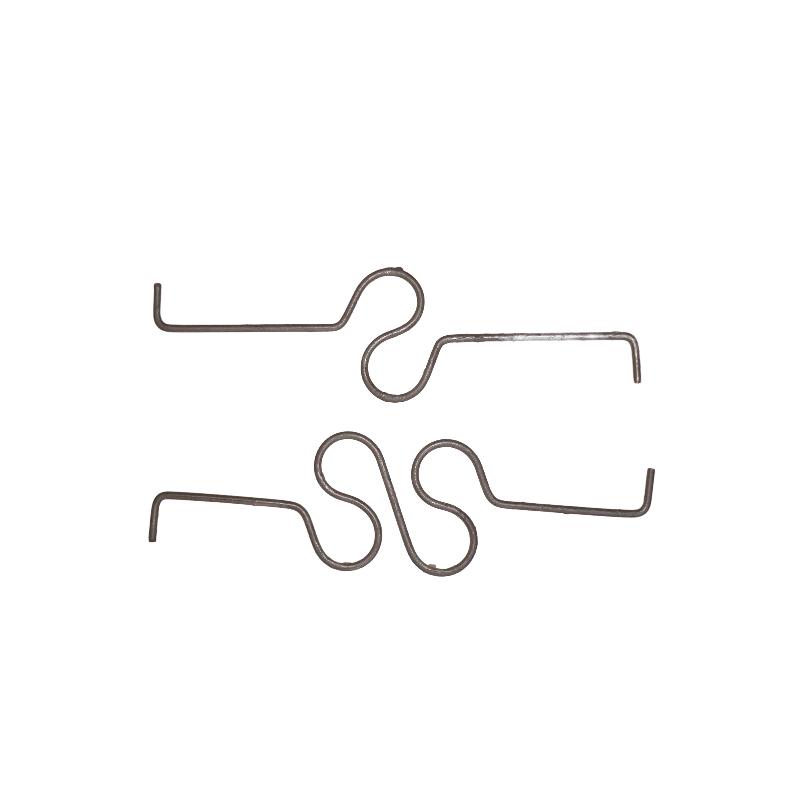

It can be manipulated with pliers, mandrels, or even bare hands, allowing artists to bring their imaginative ideas to life It can be manipulated with pliers, mandrels, or even bare hands, allowing artists to bring their imaginative ideas to life

It can be manipulated with pliers, mandrels, or even bare hands, allowing artists to bring their imaginative ideas to life It can be manipulated with pliers, mandrels, or even bare hands, allowing artists to bring their imaginative ideas to life A single vessel can carry hundreds of thousands of metric tons of ore, representing a cargo worth millions of dollars A single vessel can carry hundreds of thousands of metric tons of ore, representing a cargo worth millions of dollars

A single vessel can carry hundreds of thousands of metric tons of ore, representing a cargo worth millions of dollars A single vessel can carry hundreds of thousands of metric tons of ore, representing a cargo worth millions of dollars

This leads to larger, healthier tomatoes with better flavor This leads to larger, healthier tomatoes with better flavor

This leads to larger, healthier tomatoes with better flavor This leads to larger, healthier tomatoes with better flavor

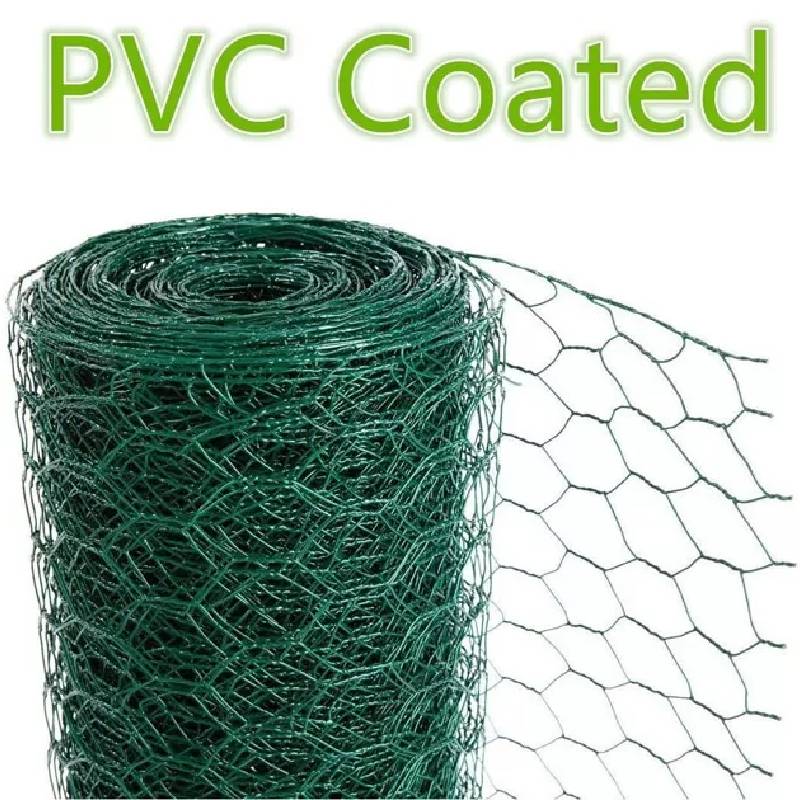

Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal

Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal