Silicone oil seals, which are also called VMQ, have strong resistance to temperature, which ranges from -140 degrees Fahrenheit to 392 degrees Fahrenheit. They are also resistant to ozone, light, and harsh weather conditions. Silicone is frequently used in hydraulics and pneumatics, as well as in the food and medical industries. Due to the material’s transparency and flexibility, it’s commonly chosen for the manufacturing of o-rings, molded parts, and flat seals, as well as electrical insulators.

Home

Home

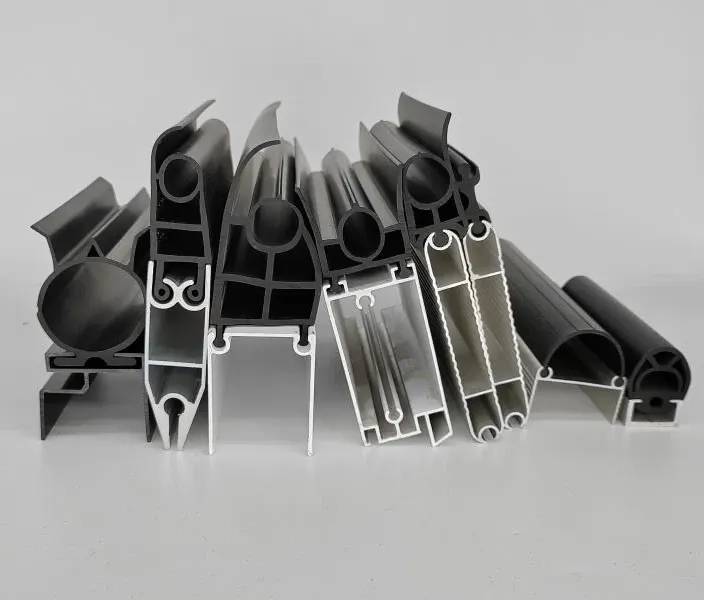

It can be used in a wide range of applications, from passenger cars to commercial vehicles, and from small engines to large industrial machinery It can be used in a wide range of applications, from passenger cars to commercial vehicles, and from small engines to large industrial machinery

It can be used in a wide range of applications, from passenger cars to commercial vehicles, and from small engines to large industrial machinery It can be used in a wide range of applications, from passenger cars to commercial vehicles, and from small engines to large industrial machinery