CE marking is a certification mark that indicates a product's compliance with European health, safety, and environmental protection standards. The initials CE stand for Conformité Européenne, which translates to European Conformity. This certification is mandatory for certain products sold within the European Economic Area (EEA) and acts as a passport for market entry. When you see the CE mark on a shower door seal strip, it signifies that the product adheres to the relevant EU directives, ensuring not only safety but also quality.

Home

Home

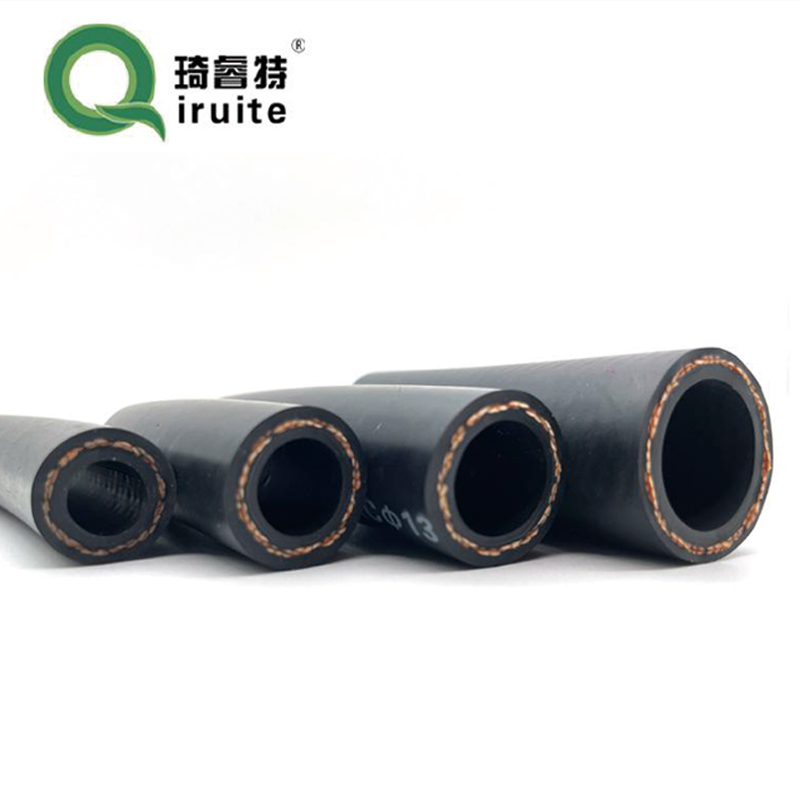

This pressure acts on the steering cylinder, creating a force that helps to move the steering gear, thus making it easier for the driver to turn the wheels This pressure acts on the steering cylinder, creating a force that helps to move the steering gear, thus making it easier for the driver to turn the wheels

This pressure acts on the steering cylinder, creating a force that helps to move the steering gear, thus making it easier for the driver to turn the wheels This pressure acts on the steering cylinder, creating a force that helps to move the steering gear, thus making it easier for the driver to turn the wheels

Ignoring these signs could lead to a sudden loss of steering ability, which is dangerous at any speed and particularly hazardous at high speeds or while navigating busy roads Ignoring these signs could lead to a sudden loss of steering ability, which is dangerous at any speed and particularly hazardous at high speeds or while navigating busy roads

Ignoring these signs could lead to a sudden loss of steering ability, which is dangerous at any speed and particularly hazardous at high speeds or while navigating busy roads Ignoring these signs could lead to a sudden loss of steering ability, which is dangerous at any speed and particularly hazardous at high speeds or while navigating busy roads When the driver applies the brake pedal, the fluid pressure travels through the hose, causing the brake pads or shoes to press against the rotor or drum, thus slowing down or stopping the vehicle When the driver applies the brake pedal, the fluid pressure travels through the hose, causing the brake pads or shoes to press against the rotor or drum, thus slowing down or stopping the vehicle

When the driver applies the brake pedal, the fluid pressure travels through the hose, causing the brake pads or shoes to press against the rotor or drum, thus slowing down or stopping the vehicle When the driver applies the brake pedal, the fluid pressure travels through the hose, causing the brake pads or shoes to press against the rotor or drum, thus slowing down or stopping the vehicle This can be done by disconnecting the hose from the power steering pump and allowing the fluid to drain into a pan This can be done by disconnecting the hose from the power steering pump and allowing the fluid to drain into a pan

This can be done by disconnecting the hose from the power steering pump and allowing the fluid to drain into a pan This can be done by disconnecting the hose from the power steering pump and allowing the fluid to drain into a pan Look for hoses with flexible, bend-resistant construction and swivel points at the connection points to minimize kinking Look for hoses with flexible, bend-resistant construction and swivel points at the connection points to minimize kinking

Look for hoses with flexible, bend-resistant construction and swivel points at the connection points to minimize kinking Look for hoses with flexible, bend-resistant construction and swivel points at the connection points to minimize kinking The detailed instructions provided with the kit make it simple for even the most novice mechanic to replace the old hoses with minimal effort The detailed instructions provided with the kit make it simple for even the most novice mechanic to replace the old hoses with minimal effort

The detailed instructions provided with the kit make it simple for even the most novice mechanic to replace the old hoses with minimal effort The detailed instructions provided with the kit make it simple for even the most novice mechanic to replace the old hoses with minimal effort