stainless steel pricelist

Home

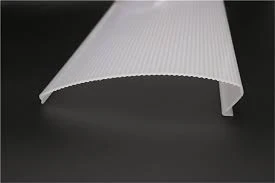

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

The rubber lip, in contact with the shaft, forms a tight seal that can withstand varying temperatures, pressures, and speeds The rubber lip, in contact with the shaft, forms a tight seal that can withstand varying temperatures, pressures, and speeds

The rubber lip, in contact with the shaft, forms a tight seal that can withstand varying temperatures, pressures, and speeds The rubber lip, in contact with the shaft, forms a tight seal that can withstand varying temperatures, pressures, and speeds

The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild

The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild The kit should provide clear instructions to guide you through this process, ensuring a precise and efficient rebuild Most kits come with detailed instructions that make it easy for even the most novice mechanic to replace worn or damaged seals quickly and easily Most kits come with detailed instructions that make it easy for even the most novice mechanic to replace worn or damaged seals quickly and easily

Most kits come with detailed instructions that make it easy for even the most novice mechanic to replace worn or damaged seals quickly and easily Most kits come with detailed instructions that make it easy for even the most novice mechanic to replace worn or damaged seals quickly and easily