stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

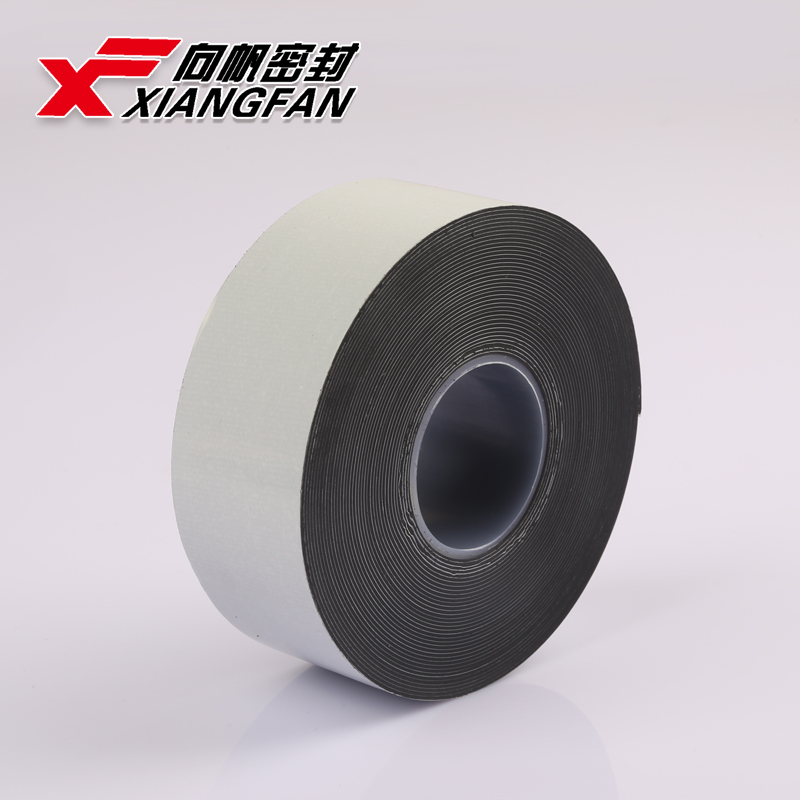

- · sponge seal service

- · felt window seal strip suppliers

With a wide range of colors and patterns available, it can be creatively used to create visually appealing designs or to brand the facility With a wide range of colors and patterns available, it can be creatively used to create visually appealing designs or to brand the facility

With a wide range of colors and patterns available, it can be creatively used to create visually appealing designs or to brand the facility With a wide range of colors and patterns available, it can be creatively used to create visually appealing designs or to brand the facility

HVAC systems It is used to insulate ductwork, pipes, and other components in heating, ventilation, and air conditioning (HVAC) systems to improve energy efficiency and reduce noise HVAC systems It is used to insulate ductwork, pipes, and other components in heating, ventilation, and air conditioning (HVAC) systems to improve energy efficiency and reduce noise

HVAC systems It is used to insulate ductwork, pipes, and other components in heating, ventilation, and air conditioning (HVAC) systems to improve energy efficiency and reduce noise HVAC systems It is used to insulate ductwork, pipes, and other components in heating, ventilation, and air conditioning (HVAC) systems to improve energy efficiency and reduce noise It also has a low flammability rating, which makes it safer to use in buildings and other structures It also has a low flammability rating, which makes it safer to use in buildings and other structures

It also has a low flammability rating, which makes it safer to use in buildings and other structures It also has a low flammability rating, which makes it safer to use in buildings and other structures