stainless steel pricelist

Home

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

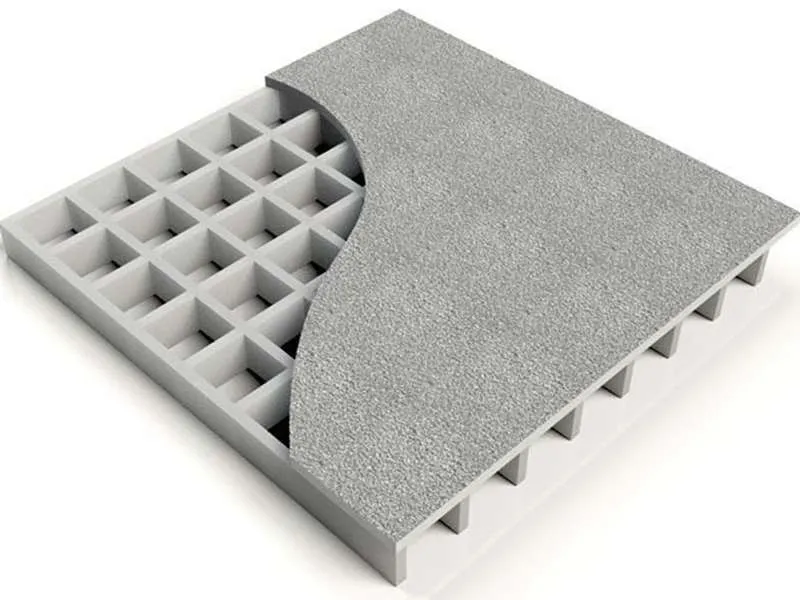

FRP manhole covers can be colored and textured to blend seamlessly into pavements or stand out as safety markers FRP manhole covers can be colored and textured to blend seamlessly into pavements or stand out as safety markers

FRP manhole covers can be colored and textured to blend seamlessly into pavements or stand out as safety markers FRP manhole covers can be colored and textured to blend seamlessly into pavements or stand out as safety markers If you will be using your jack hammer for extended periods of time or in demanding conditions, opting for a bigger model may be a wise choice If you will be using your jack hammer for extended periods of time or in demanding conditions, opting for a bigger model may be a wise choice

If you will be using your jack hammer for extended periods of time or in demanding conditions, opting for a bigger model may be a wise choice If you will be using your jack hammer for extended periods of time or in demanding conditions, opting for a bigger model may be a wise choice

This versatility allows for maximum efficiency and performance in a variety of settings This versatility allows for maximum efficiency and performance in a variety of settings

This versatility allows for maximum efficiency and performance in a variety of settings This versatility allows for maximum efficiency and performance in a variety of settings Due to the size, these bits can generate immense torque, so wearing safety glasses and gloves is essential to protect against flying debris and potential injuries Due to the size, these bits can generate immense torque, so wearing safety glasses and gloves is essential to protect against flying debris and potential injuries

Due to the size, these bits can generate immense torque, so wearing safety glasses and gloves is essential to protect against flying debris and potential injuries Due to the size, these bits can generate immense torque, so wearing safety glasses and gloves is essential to protect against flying debris and potential injuries Meniscus Top:

Meniscus Top: