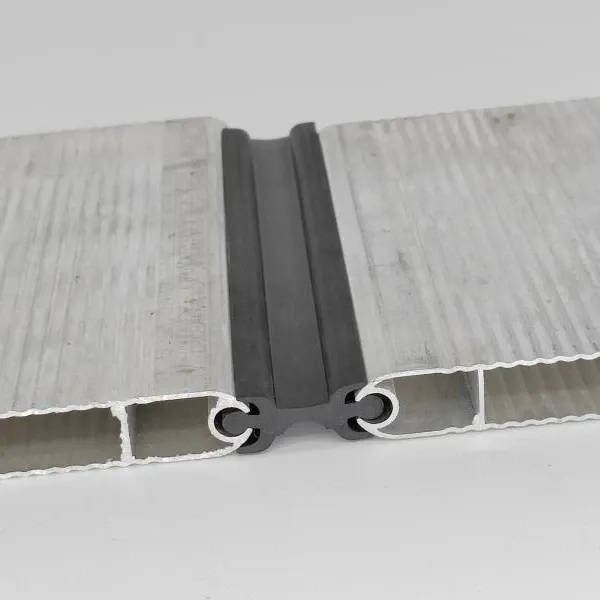

Opting for OEM flat chrome trim strips ensures that you're investing in products that meet high manufacturing standards. OEM parts are designed to withstand the rigors of daily use, including exposure to harsh weather conditions, UV rays, and physical wear. Unlike aftermarket alternatives, which may compromise on quality, OEM trim strips provide durability and longevity. This means that the trim will maintain its shine and structural integrity over time, providing sustained visual appeal and protection to the underlying surfaces.

Home

Home

Conversely, well-maintained spark plugs ensure smooth idling, improved throttle response, and enhanced engine life Conversely, well-maintained spark plugs ensure smooth idling, improved throttle response, and enhanced engine life

Conversely, well-maintained spark plugs ensure smooth idling, improved throttle response, and enhanced engine life Conversely, well-maintained spark plugs ensure smooth idling, improved throttle response, and enhanced engine life