stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

Similarly, in retail stores, they guide customers to maintain a safe distance from each other at checkout counters Similarly, in retail stores, they guide customers to maintain a safe distance from each other at checkout counters

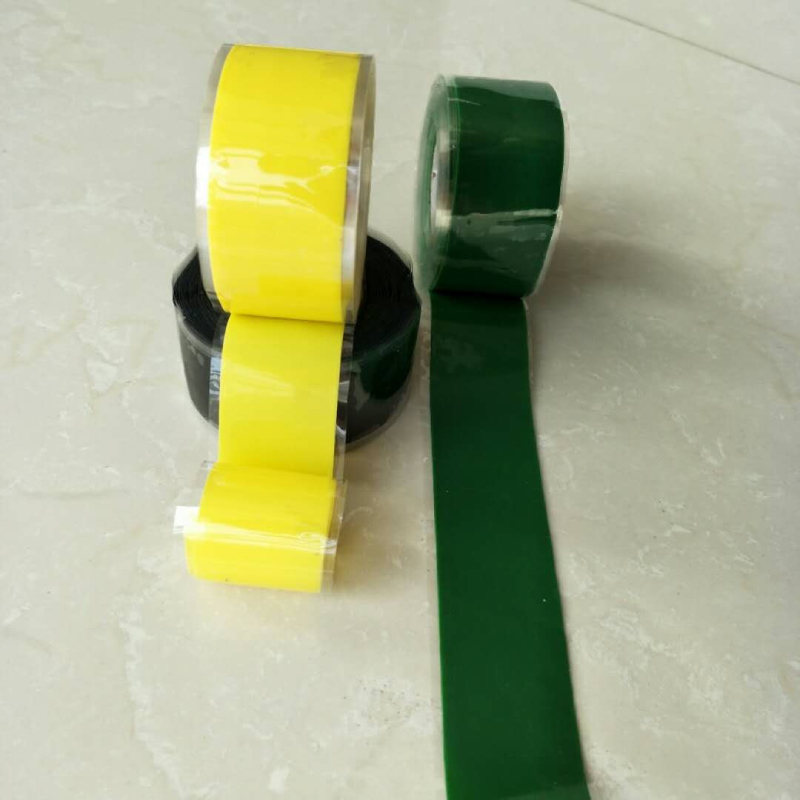

Similarly, in retail stores, they guide customers to maintain a safe distance from each other at checkout counters Similarly, in retail stores, they guide customers to maintain a safe distance from each other at checkout counters In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock

In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment