CE, which stands for Conformité Européenne (European Conformity), is a certification mark that indicates a product's compliance with EU legislation. It is mandatory for certain products sold within the European Economic Area (EEA). High polymer materials, often used in various applications ranging from industrial manufacturing to consumer goods, must undergo rigorous testing to achieve this certification. The CE mark signifies that the product is safe for use, complies with environmental regulations, and meets all essential requirements laid out by the EU.

Home

Home

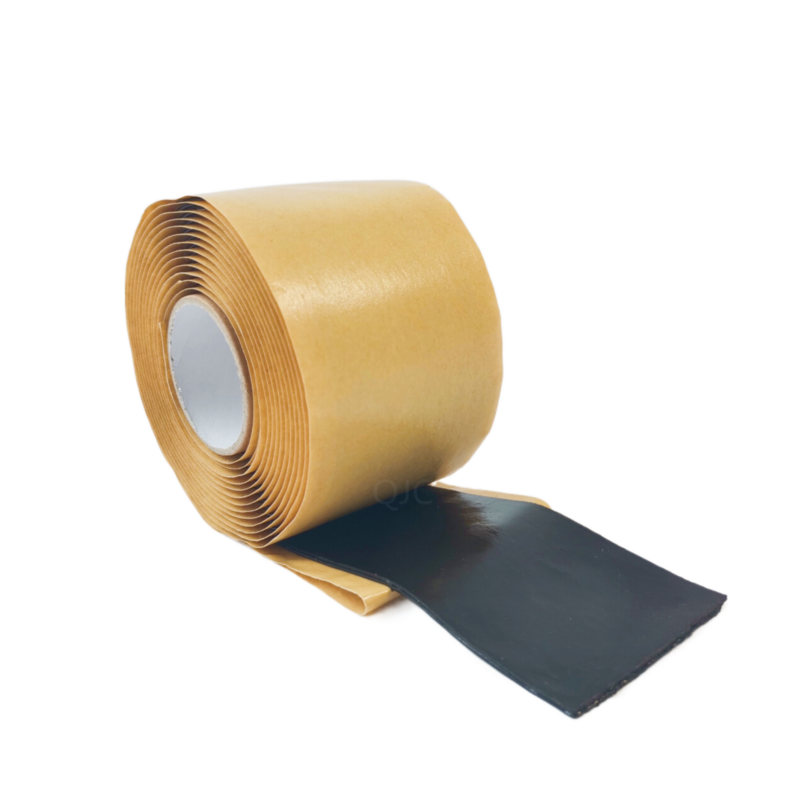

Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures

Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures In automotive applications, it can seal fuel lines and hydraulic connections In automotive applications, it can seal fuel lines and hydraulic connections

In automotive applications, it can seal fuel lines and hydraulic connections In automotive applications, it can seal fuel lines and hydraulic connections