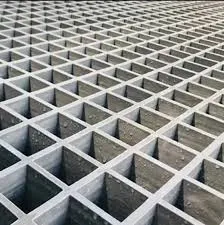

The selection of the resin option also depends upon the purpose of use. For the general purposes Orthophthalic Polyester is more suitable. Some other resin options are Vinyl Ester, Isophthalic Polyester (or ISO), Fire Retardant and USDA certified. All resin options are UV Resistant and are designed for different purposes and conditions.

Available in various colors and styles, such as green, yellow, grey, orange and various other custom colors, fiberglass grating is more appealing in look as well. To ensure the longevity of the product, color is permanently added to the resin formula. The color and style of the grating are decided, while keeping the safety hazards in account. Some of the most prominent industries that use fiberglass gratings are waste water treatment plants, food processing plants, aquariums, power plants, chemical plants, lift stations, plating shops and also plants with canning and beverage facilities.

Home

Home

It is also important to regularly inspect the extension rod for signs of wear or damage and replace it if necessary to ensure safe and efficient drilling operations It is also important to regularly inspect the extension rod for signs of wear or damage and replace it if necessary to ensure safe and efficient drilling operations

It is also important to regularly inspect the extension rod for signs of wear or damage and replace it if necessary to ensure safe and efficient drilling operations It is also important to regularly inspect the extension rod for signs of wear or damage and replace it if necessary to ensure safe and efficient drilling operations

Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas

Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Its lightweight characteristic simplifies installation and maintenance, while its strength withstands the constant agitation and pressure exerted during the aeration process Its lightweight characteristic simplifies installation and maintenance, while its strength withstands the constant agitation and pressure exerted during the aeration process

Its lightweight characteristic simplifies installation and maintenance, while its strength withstands the constant agitation and pressure exerted during the aeration process Its lightweight characteristic simplifies installation and maintenance, while its strength withstands the constant agitation and pressure exerted during the aeration process