stainless steel pricelist

Home

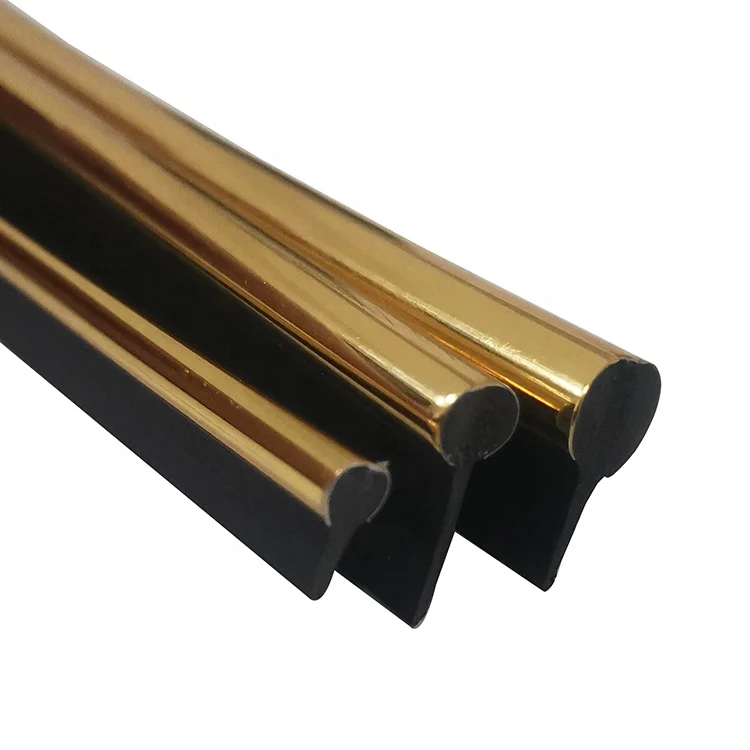

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

Fasteners must be properly torqued to the manufacturer's specifications to ensure that they provide the necessary clamping force to hold parts together securely Fasteners must be properly torqued to the manufacturer's specifications to ensure that they provide the necessary clamping force to hold parts together securely

Fasteners must be properly torqued to the manufacturer's specifications to ensure that they provide the necessary clamping force to hold parts together securely Fasteners must be properly torqued to the manufacturer's specifications to ensure that they provide the necessary clamping force to hold parts together securely

This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures

This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures

They also provide excellent resistance to shear and tensile forces, ensuring durability and resilience under various environmental conditions They also provide excellent resistance to shear and tensile forces, ensuring durability and resilience under various environmental conditions

They also provide excellent resistance to shear and tensile forces, ensuring durability and resilience under various environmental conditions They also provide excellent resistance to shear and tensile forces, ensuring durability and resilience under various environmental conditions Construction sites utilize them for quick and reliable framework connections, while electronic devices employ miniature versions for compact yet robust internal fastening Construction sites utilize them for quick and reliable framework connections, while electronic devices employ miniature versions for compact yet robust internal fastening

Construction sites utilize them for quick and reliable framework connections, while electronic devices employ miniature versions for compact yet robust internal fastening Construction sites utilize them for quick and reliable framework connections, while electronic devices employ miniature versions for compact yet robust internal fastening