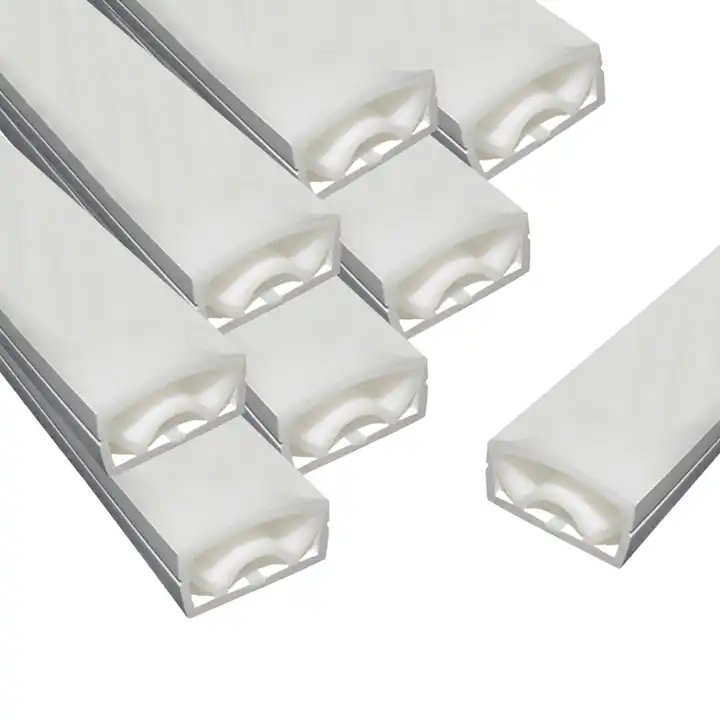

Wardrobe door seal strips serve multiple purposes, making them an indispensable facet of wardrobe design. Primarily, these strips are designed to prevent dust, moisture, and unwanted pests from entering the wardrobe. This not only keeps your clothing and accessories clean and fresh but also significantly extends their lifespan. Furthermore, seal strips contribute to energy efficiency by helping maintain the temperature of your closet, which is particularly important if your wardrobe is part of a climate-controlled room.

Home

Home