stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

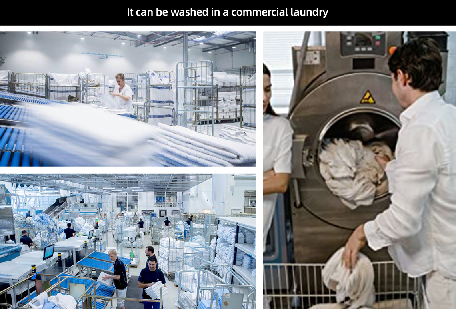

The bedsheet becomes a canvas upon which one can paint with colors and designs, reflecting moods and tastes without overwhelming the space The bedsheet becomes a canvas upon which one can paint with colors and designs, reflecting moods and tastes without overwhelming the space

The bedsheet becomes a canvas upon which one can paint with colors and designs, reflecting moods and tastes without overwhelming the space The bedsheet becomes a canvas upon which one can paint with colors and designs, reflecting moods and tastes without overwhelming the space Wide fabric is also commonly used in bridal wear and evening gowns, where the extra width allows for the creation of dramatic silhouettes and flowing lines Wide fabric is also commonly used in bridal wear and evening gowns, where the extra width allows for the creation of dramatic silhouettes and flowing lines

Wide fabric is also commonly used in bridal wear and evening gowns, where the extra width allows for the creation of dramatic silhouettes and flowing lines Wide fabric is also commonly used in bridal wear and evening gowns, where the extra width allows for the creation of dramatic silhouettes and flowing lines They may also be dyed using low-impact dyes, which have a lesser impact on the environment than traditional chemical dyes They may also be dyed using low-impact dyes, which have a lesser impact on the environment than traditional chemical dyes

They may also be dyed using low-impact dyes, which have a lesser impact on the environment than traditional chemical dyes They may also be dyed using low-impact dyes, which have a lesser impact on the environment than traditional chemical dyes

This balance between synthetic and natural materials results in a pleasant sleeping experience suitable for various climates and personal preferences This balance between synthetic and natural materials results in a pleasant sleeping experience suitable for various climates and personal preferences

This balance between synthetic and natural materials results in a pleasant sleeping experience suitable for various climates and personal preferences This balance between synthetic and natural materials results in a pleasant sleeping experience suitable for various climates and personal preferences