stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

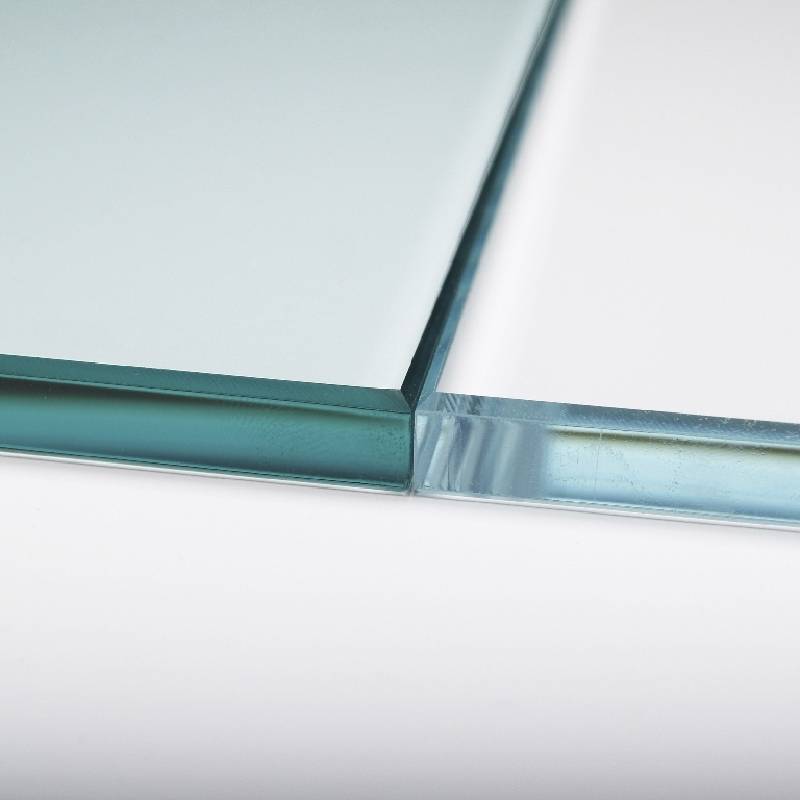

Buyers must be vigilant about these specifications, seeking certifications like EN 12150 for European Union or equivalent standards elsewhere, which guarantee the product's compliance with international safety norms Buyers must be vigilant about these specifications, seeking certifications like EN 12150 for European Union or equivalent standards elsewhere, which guarantee the product's compliance with international safety norms

Buyers must be vigilant about these specifications, seeking certifications like EN 12150 for European Union or equivalent standards elsewhere, which guarantee the product's compliance with international safety norms Buyers must be vigilant about these specifications, seeking certifications like EN 12150 for European Union or equivalent standards elsewhere, which guarantee the product's compliance with international safety norms During peak construction seasons or economic booms, when the demand for glass is high, prices tend to rise During peak construction seasons or economic booms, when the demand for glass is high, prices tend to rise

During peak construction seasons or economic booms, when the demand for glass is high, prices tend to rise During peak construction seasons or economic booms, when the demand for glass is high, prices tend to rise

Whether it's placed in an entryway, bedroom, or living room, a silver traditional mirror is sure to draw the eye and make a statement Whether it's placed in an entryway, bedroom, or living room, a silver traditional mirror is sure to draw the eye and make a statement

Whether it's placed in an entryway, bedroom, or living room, a silver traditional mirror is sure to draw the eye and make a statement Whether it's placed in an entryway, bedroom, or living room, a silver traditional mirror is sure to draw the eye and make a statement