stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

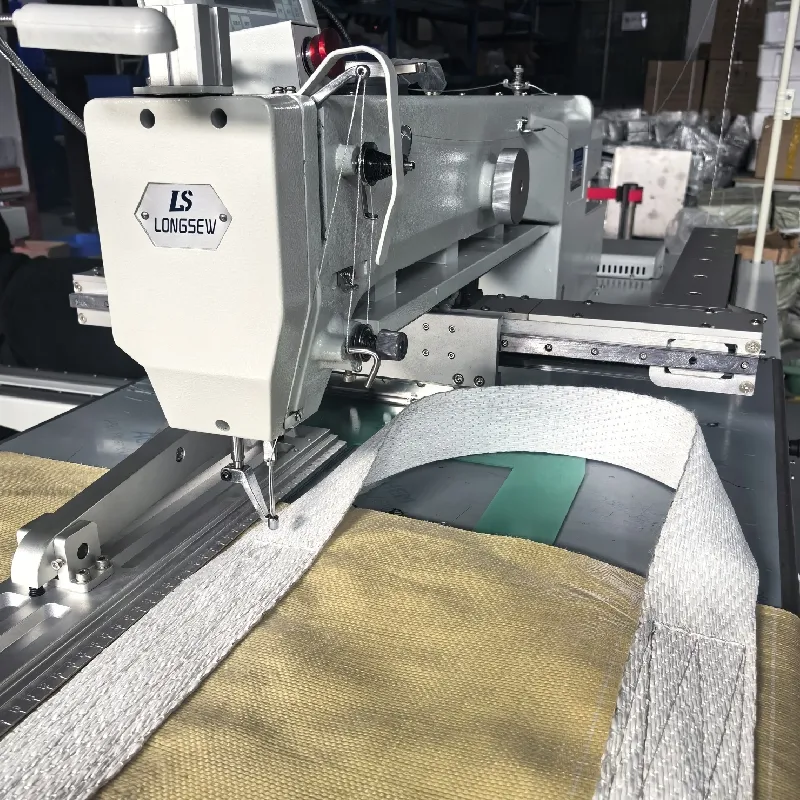

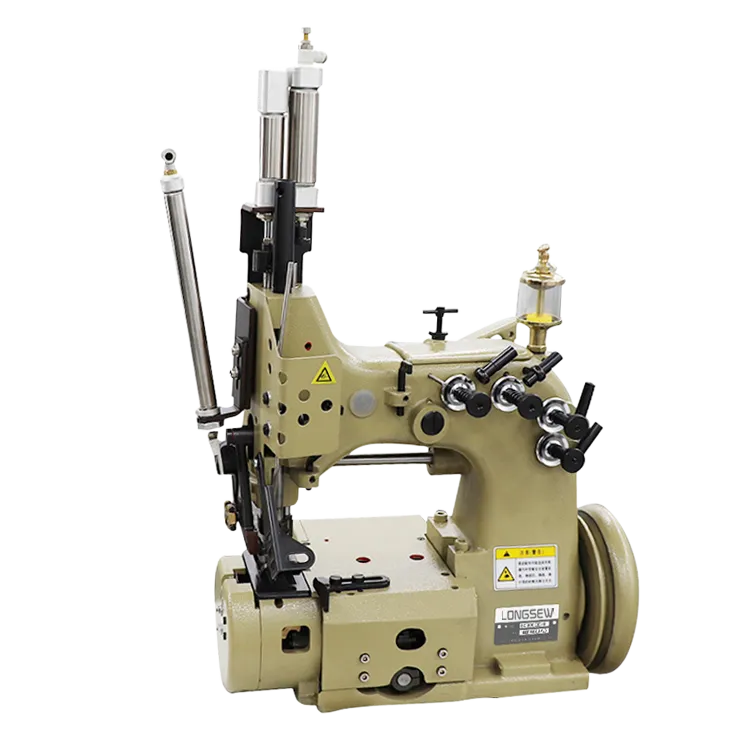

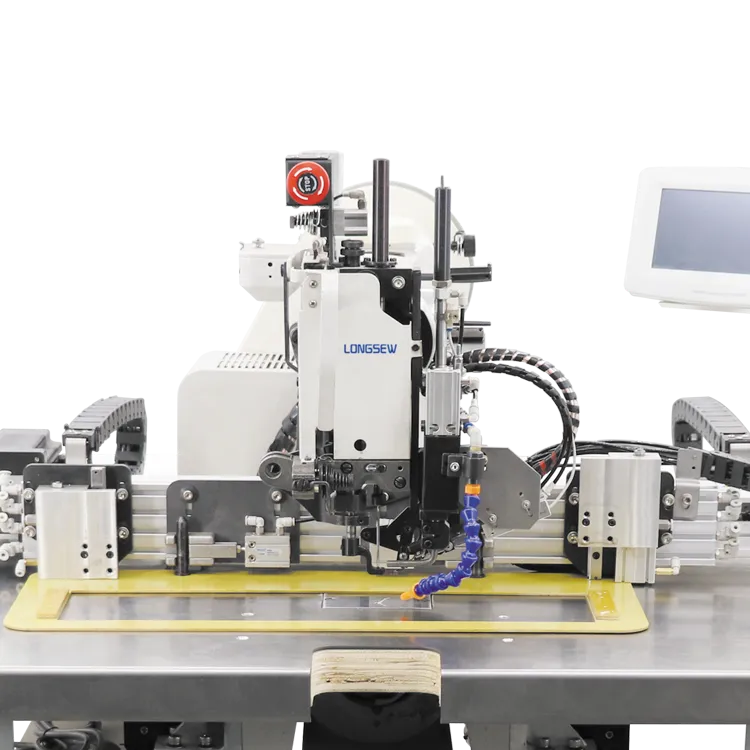

With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged

With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged