In conclusion, CE certification for door and window sealing strips is not just a regulatory checkbox but a commitment to quality, safety, and environmental responsibility. As consumers demand higher standards and energy efficiency, manufacturers must prioritize obtaining this certification. By doing so, they enhance their product offerings, build consumer trust, and contribute to a more sustainable future. The importance of CE certification cannot be overstated; it signifies a product’s ability to perform safely and efficiently in an ever-evolving market, ultimately benefiting both manufacturers and consumers alike.

Home

Home

In mining, it's used in sieving operations, separating minerals based on particle size In mining, it's used in sieving operations, separating minerals based on particle size

In mining, it's used in sieving operations, separating minerals based on particle size In mining, it's used in sieving operations, separating minerals based on particle size

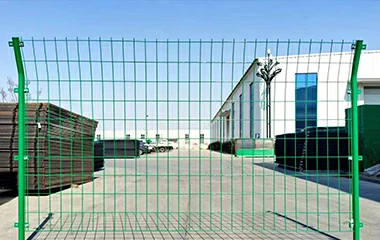

With simple installation instructions, you can quickly set up your fence without the need for professional help With simple installation instructions, you can quickly set up your fence without the need for professional help

With simple installation instructions, you can quickly set up your fence without the need for professional help With simple installation instructions, you can quickly set up your fence without the need for professional help