stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

Regular inspection and timely replacement of hydraulic cylinder seals are thus essential for forklift maintenance Regular inspection and timely replacement of hydraulic cylinder seals are thus essential for forklift maintenance

Regular inspection and timely replacement of hydraulic cylinder seals are thus essential for forklift maintenance Regular inspection and timely replacement of hydraulic cylinder seals are thus essential for forklift maintenance Factors to consider include the operating conditions, such as temperature, pressure, and the type of fluid used Factors to consider include the operating conditions, such as temperature, pressure, and the type of fluid used

Factors to consider include the operating conditions, such as temperature, pressure, and the type of fluid used Factors to consider include the operating conditions, such as temperature, pressure, and the type of fluid used

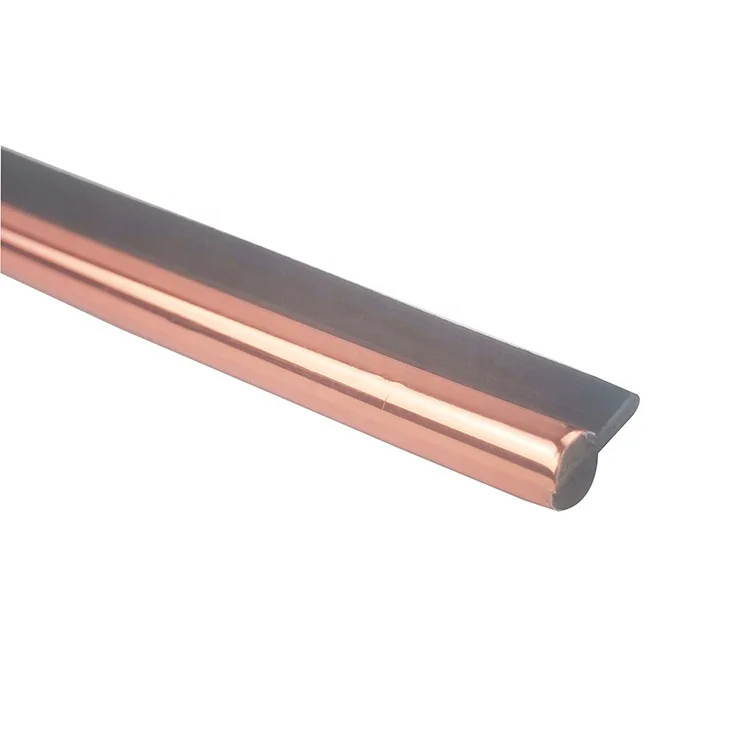

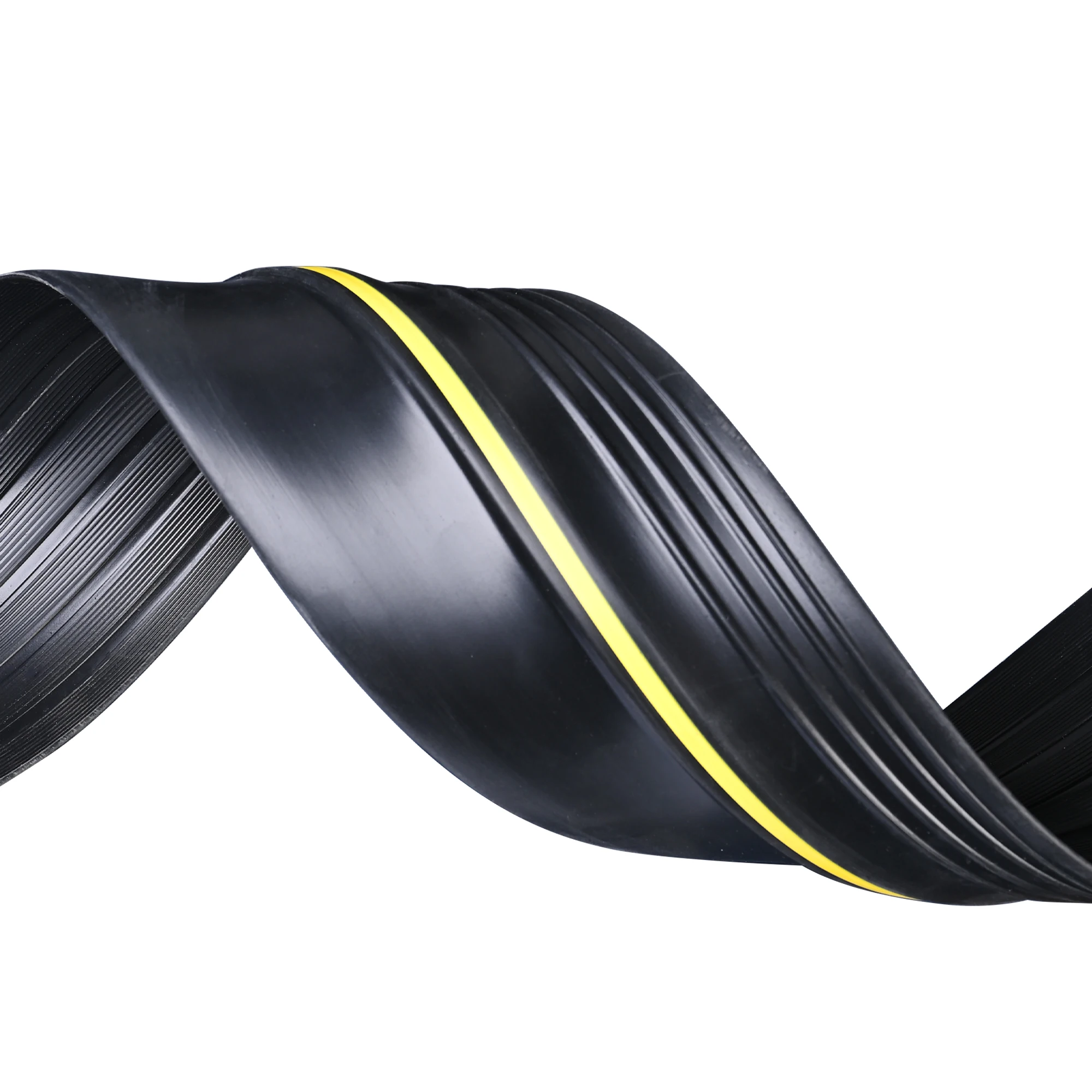

The seal is typically made from a flexible material, such as rubber or silicone, that can conform to the shape of the shaft and housing for a secure fit The seal is typically made from a flexible material, such as rubber or silicone, that can conform to the shape of the shaft and housing for a secure fit

The seal is typically made from a flexible material, such as rubber or silicone, that can conform to the shape of the shaft and housing for a secure fit The seal is typically made from a flexible material, such as rubber or silicone, that can conform to the shape of the shaft and housing for a secure fit In manufacturing plants, these seals are crucial for press machines and material handling equipment, guaranteeing reliable performance under heavy loads In manufacturing plants, these seals are crucial for press machines and material handling equipment, guaranteeing reliable performance under heavy loads

In manufacturing plants, these seals are crucial for press machines and material handling equipment, guaranteeing reliable performance under heavy loads In manufacturing plants, these seals are crucial for press machines and material handling equipment, guaranteeing reliable performance under heavy loads