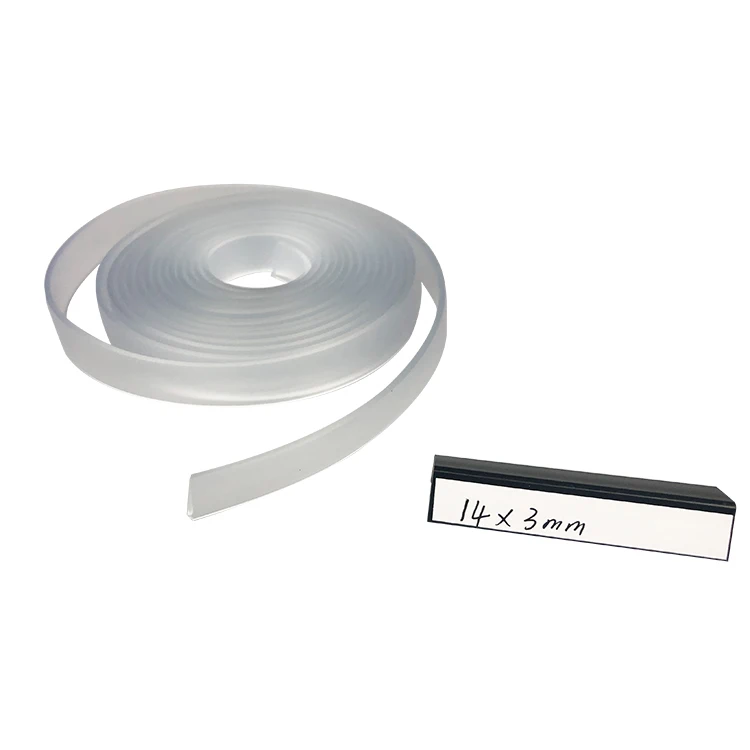

In conclusion, white rubber seal strip companies serve a crucial role in modern manufacturing and industrial applications. With their commitment to quality, innovation, and sustainability, these companies are not just meeting the sealing needs of various sectors but are also contributing positively to the environment. As industries continue to evolve, the demand for reliable sealing solutions will undoubtedly increase, positioning white rubber seal strip companies as integral players in the future of manufacturing and construction. Their expertise in producing high-quality, durable seal strips will remain essential for ensuring the efficiency, safety, and sustainability of products across the board.

Home

Home

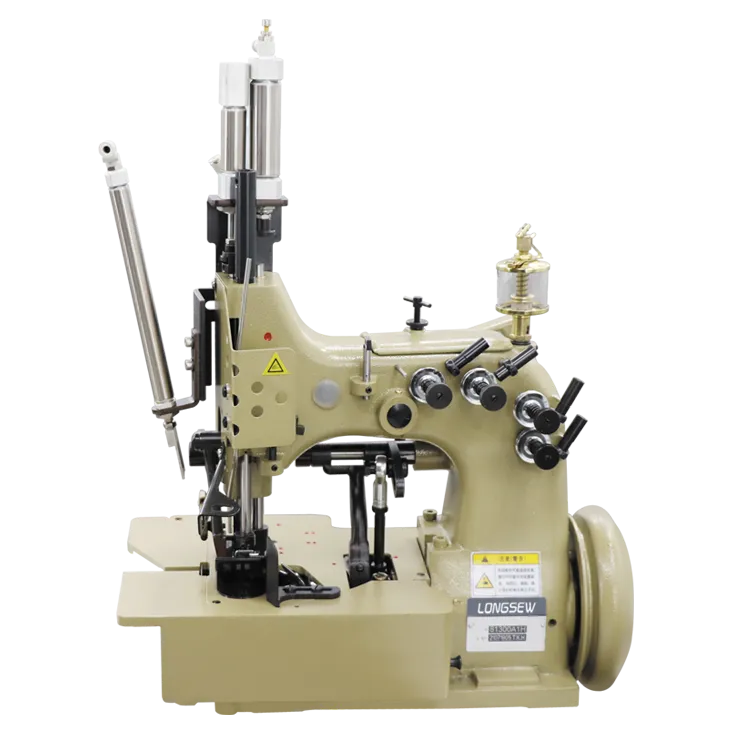

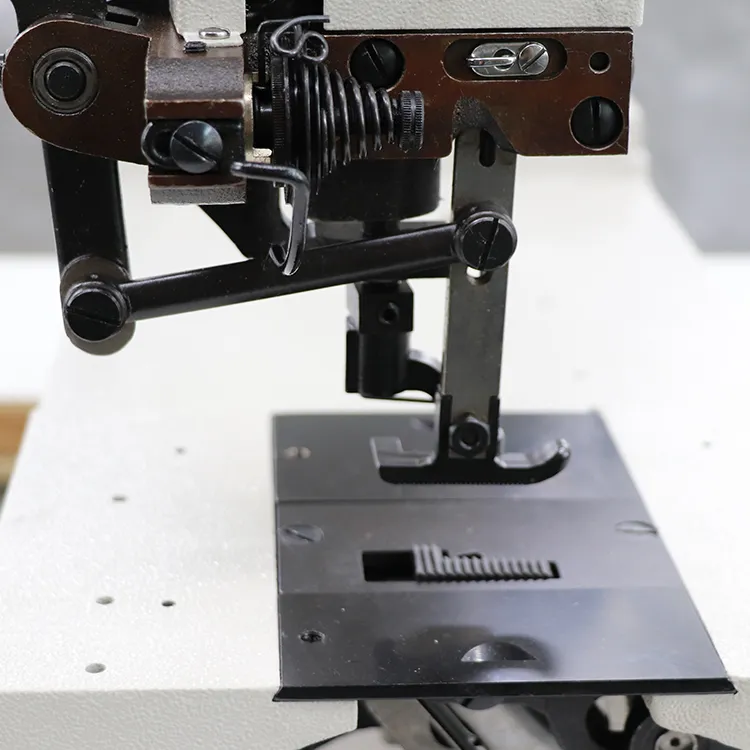

It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects

It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects