stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

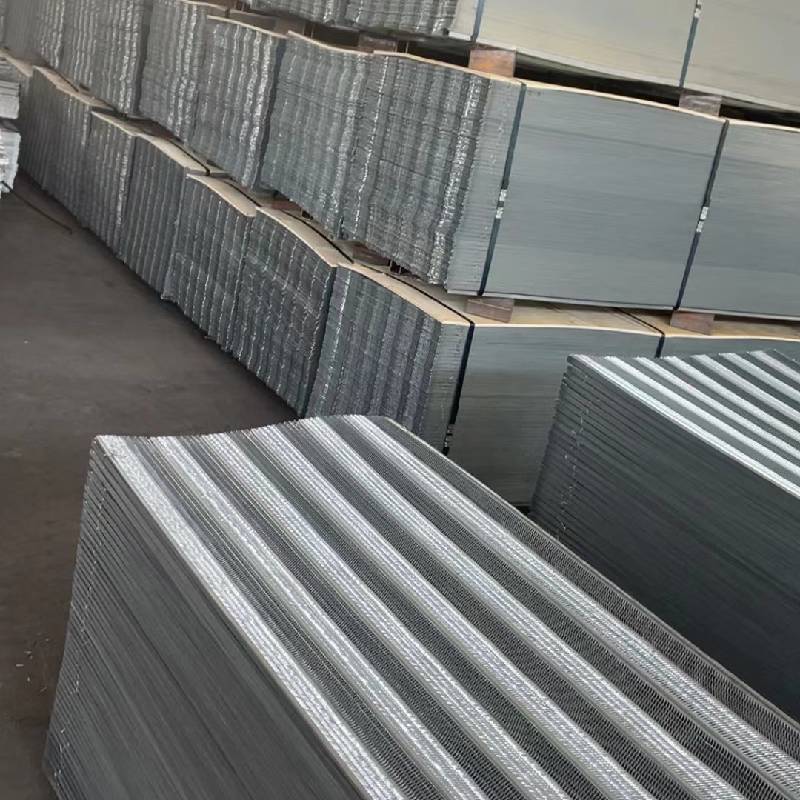

The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced

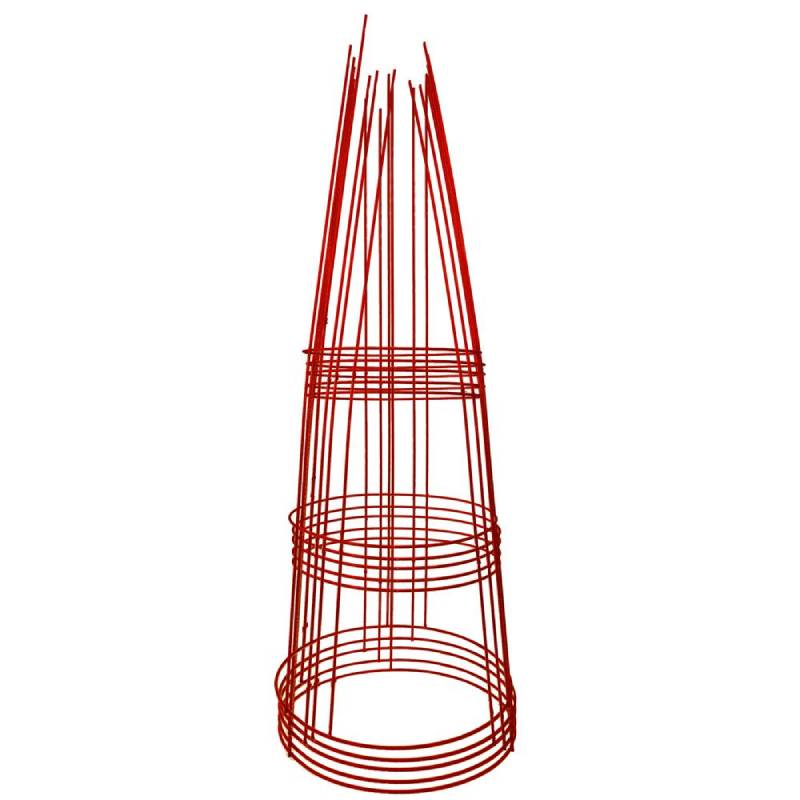

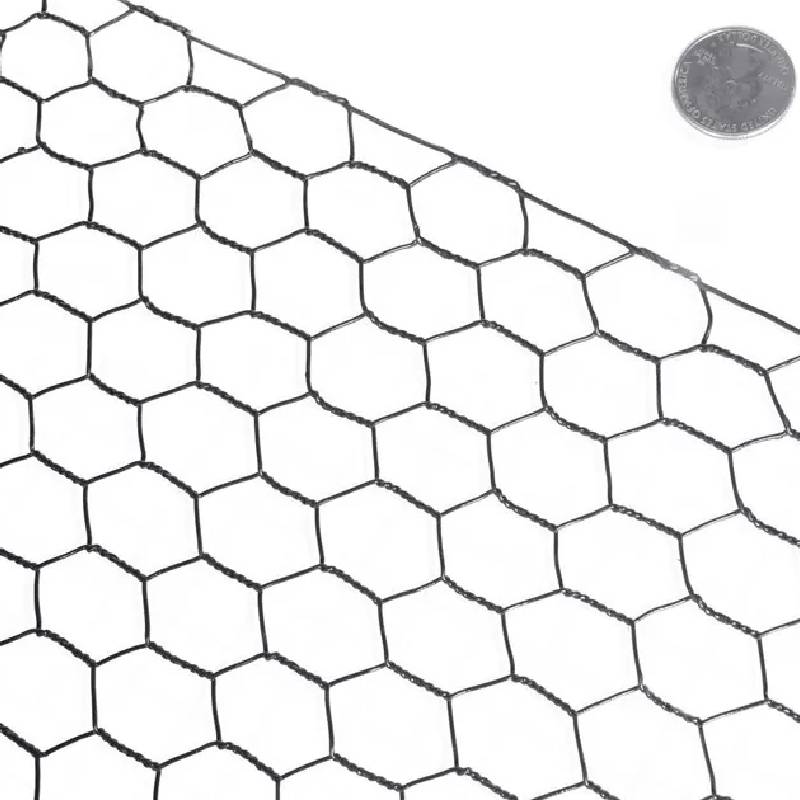

The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced It's commonly used to construct livestock pens, trellises for vines, and even in the making of hay bales It's commonly used to construct livestock pens, trellises for vines, and even in the making of hay bales

It's commonly used to construct livestock pens, trellises for vines, and even in the making of hay bales It's commonly used to construct livestock pens, trellises for vines, and even in the making of hay bales The minimalist yet industrial look of these stands adds a touch of sophistication and edginess to any decor The minimalist yet industrial look of these stands adds a touch of sophistication and edginess to any decor

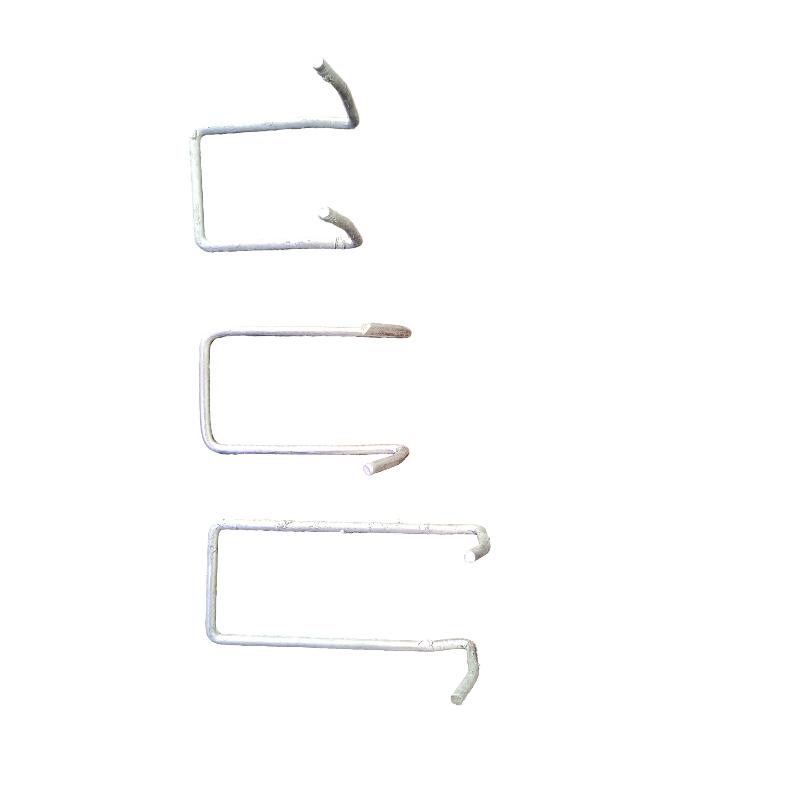

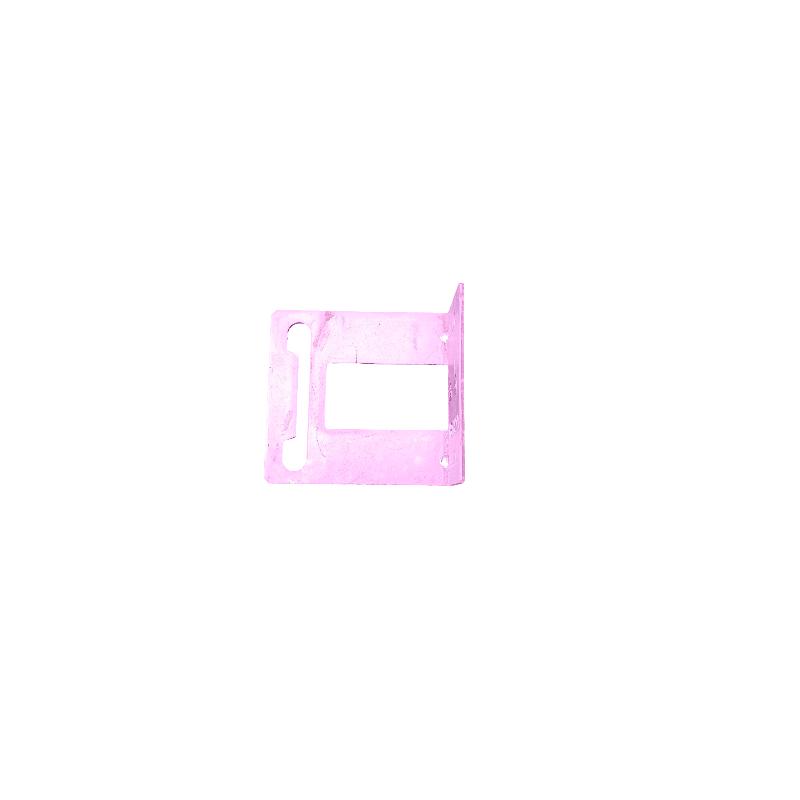

The minimalist yet industrial look of these stands adds a touch of sophistication and edginess to any decor The minimalist yet industrial look of these stands adds a touch of sophistication and edginess to any decor The choice of material, usually steel, stainless steel, or alloy, influences the spring's strength, corrosion resistance, and temperature tolerance The choice of material, usually steel, stainless steel, or alloy, influences the spring's strength, corrosion resistance, and temperature tolerance

The choice of material, usually steel, stainless steel, or alloy, influences the spring's strength, corrosion resistance, and temperature tolerance The choice of material, usually steel, stainless steel, or alloy, influences the spring's strength, corrosion resistance, and temperature tolerance

They can be used as a space-saving storage solution, allowing you to hang shelves, hooks, and other storage accessories on the grid to keep your space organized and clutter-free They can be used as a space-saving storage solution, allowing you to hang shelves, hooks, and other storage accessories on the grid to keep your space organized and clutter-free

They can be used as a space-saving storage solution, allowing you to hang shelves, hooks, and other storage accessories on the grid to keep your space organized and clutter-free They can be used as a space-saving storage solution, allowing you to hang shelves, hooks, and other storage accessories on the grid to keep your space organized and clutter-free