In the realm of creating energy-efficient spaces and enhancing comfort within our homes and workplaces, brush door seal strips have emerged as integral components. These seals are designed to create an airtight barrier between doors and their frames, preventing air leaks, dust, and noise from permeating indoor environments. As more industries recognize the benefits of effective sealing solutions, the demand for high-quality brush door seal strips has surged. This article delves into the significance of brush door seal strip manufacturers and the factors that make them essential players in the market.

Home

Home

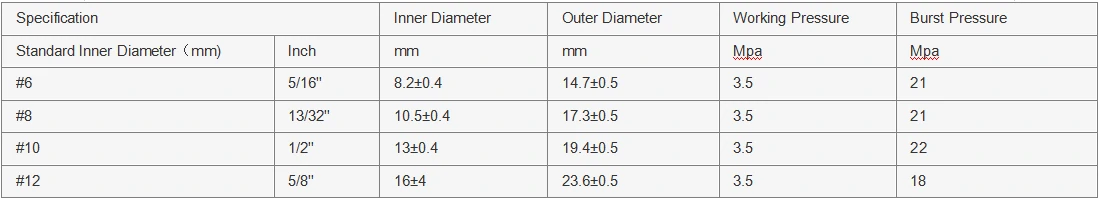

However, any compromise in the hose's integrity, such as leaks or cracks, can lead to power steering fluid loss, resulting in a steering system that feels stiff or unresponsive However, any compromise in the hose's integrity, such as leaks or cracks, can lead to power steering fluid loss, resulting in a steering system that feels stiff or unresponsive

However, any compromise in the hose's integrity, such as leaks or cracks, can lead to power steering fluid loss, resulting in a steering system that feels stiff or unresponsive However, any compromise in the hose's integrity, such as leaks or cracks, can lead to power steering fluid loss, resulting in a steering system that feels stiff or unresponsive

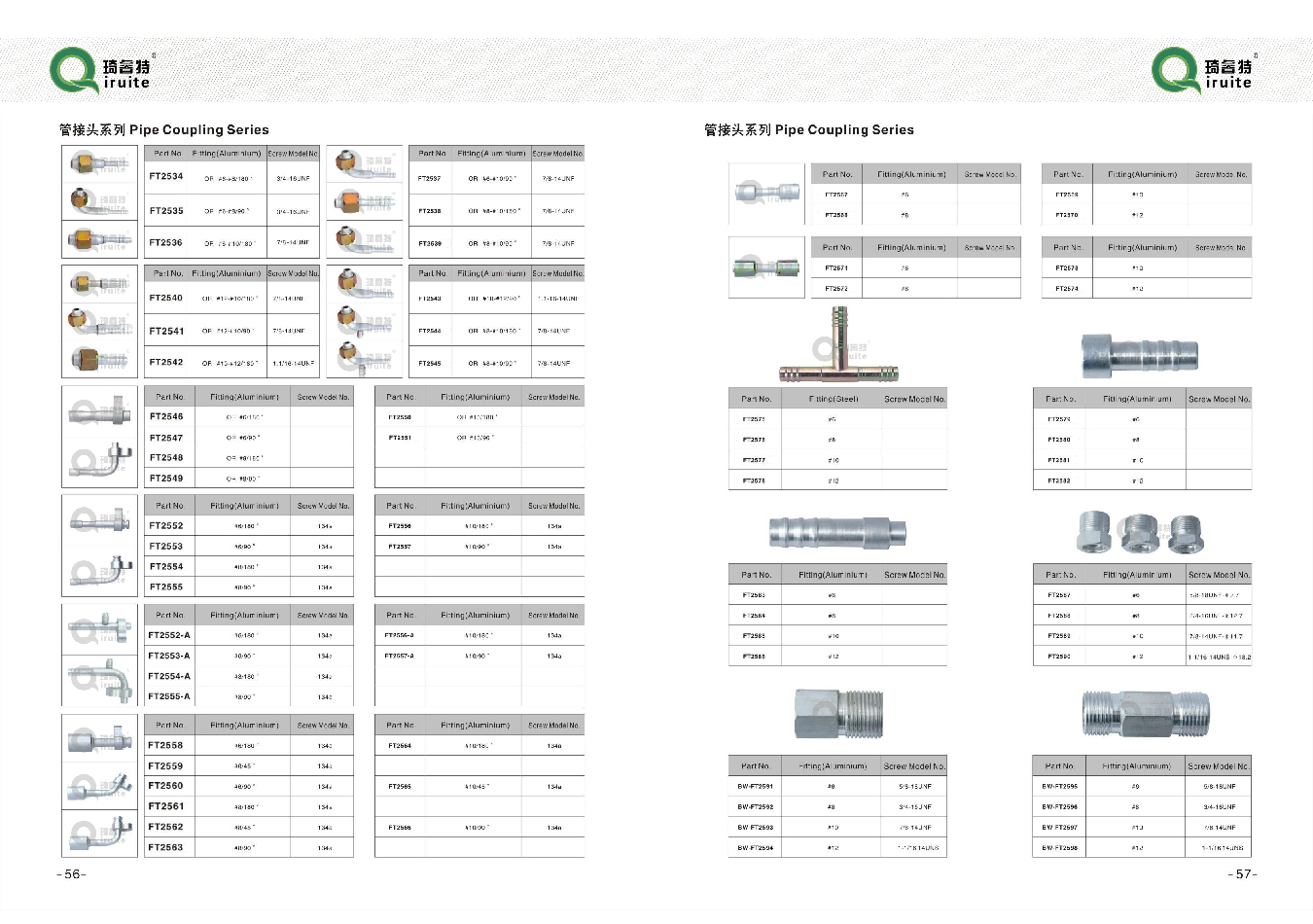

This will prevent the threads from loosening during installation This will prevent the threads from loosening during installation

This will prevent the threads from loosening during installation This will prevent the threads from loosening during installation

They are often used by professional plumbers and maintenance crews, who can access hard-to-reach areas without causing extensive damage to the surrounding pipes They are often used by professional plumbers and maintenance crews, who can access hard-to-reach areas without causing extensive damage to the surrounding pipes

They are often used by professional plumbers and maintenance crews, who can access hard-to-reach areas without causing extensive damage to the surrounding pipes They are often used by professional plumbers and maintenance crews, who can access hard-to-reach areas without causing extensive damage to the surrounding pipes

Be sure to support the hose as you remove it to prevent kinking or damage Be sure to support the hose as you remove it to prevent kinking or damage

Be sure to support the hose as you remove it to prevent kinking or damage Be sure to support the hose as you remove it to prevent kinking or damage