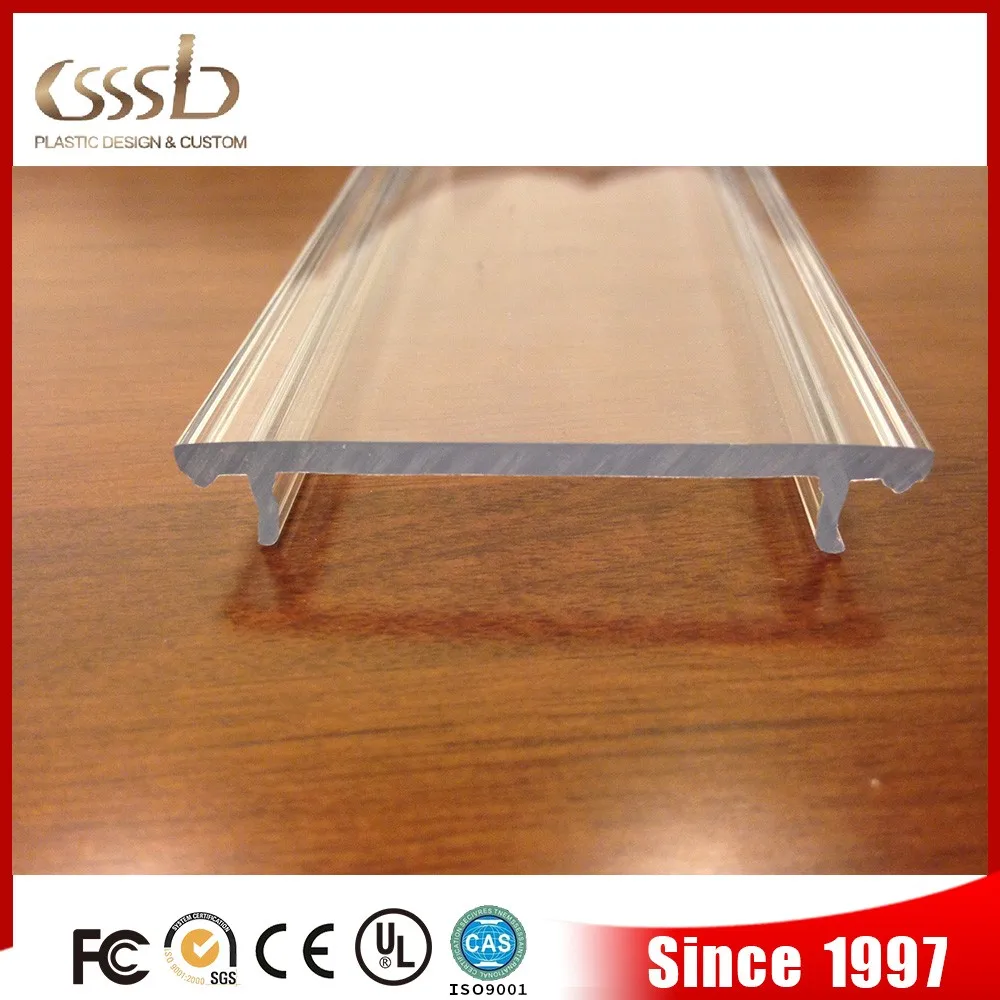

When it comes to home design and functionality, one often overlooked aspect is the sealing efficiency of doors, particularly French doors. French doors are prized for their aesthetic appeal, allowing ample natural light and creating an inviting atmosphere in living spaces. However, to maintain this beauty while ensuring energy efficiency, security, and comfort, the installation of quality seal strips is essential. In recent years, China has become a prominent player in the production of these seal strips, offering a wide range of options that cater to different needs and preferences.

Home

Home

The efficiency of the coalescing filter depends on factors such as the flow rate, viscosity of the liquid, and the size and type of contaminants present in the fluid The efficiency of the coalescing filter depends on factors such as the flow rate, viscosity of the liquid, and the size and type of contaminants present in the fluid

The efficiency of the coalescing filter depends on factors such as the flow rate, viscosity of the liquid, and the size and type of contaminants present in the fluid The efficiency of the coalescing filter depends on factors such as the flow rate, viscosity of the liquid, and the size and type of contaminants present in the fluid