stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

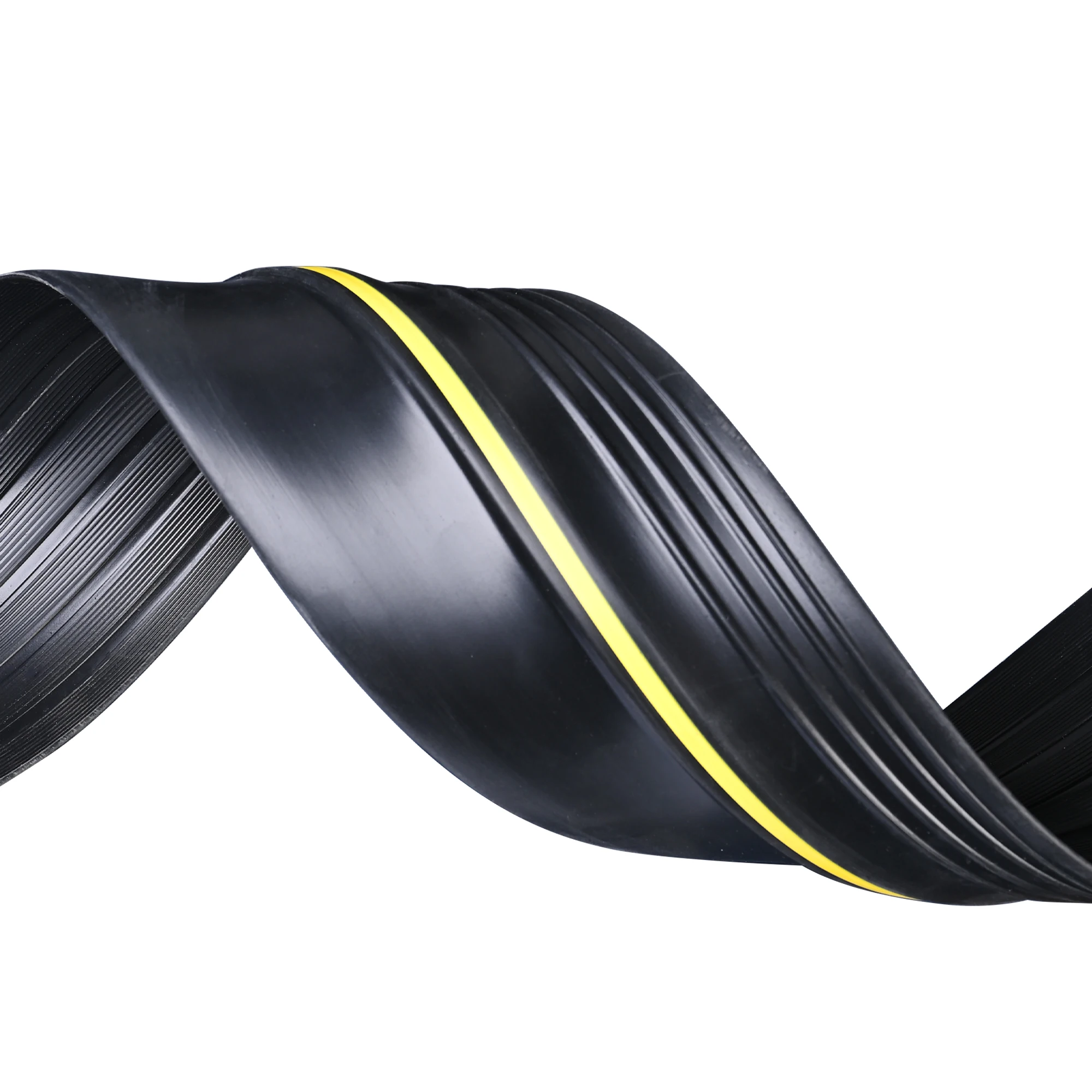

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

The robust nature of this wire allows it to support the weight of heavy vegetation, making it ideal for trellising tomatoes or training grapevines The robust nature of this wire allows it to support the weight of heavy vegetation, making it ideal for trellising tomatoes or training grapevines

The robust nature of this wire allows it to support the weight of heavy vegetation, making it ideal for trellising tomatoes or training grapevines The robust nature of this wire allows it to support the weight of heavy vegetation, making it ideal for trellising tomatoes or training grapevines