stainless steel pricelist

Home

Home- · oem silicone door seal strip

- · oem door bottom strip seal

- · car door rubber seal strip service

- · best side light single edge aluminum

- · threshold seal strip manufacturer

- · tile seal strip pricelist

- · rubber door bottom seal strip manufacturer

- · china sliding shower door seal strip

- · china shower door hinge seal strip

- · china channel letter panel material

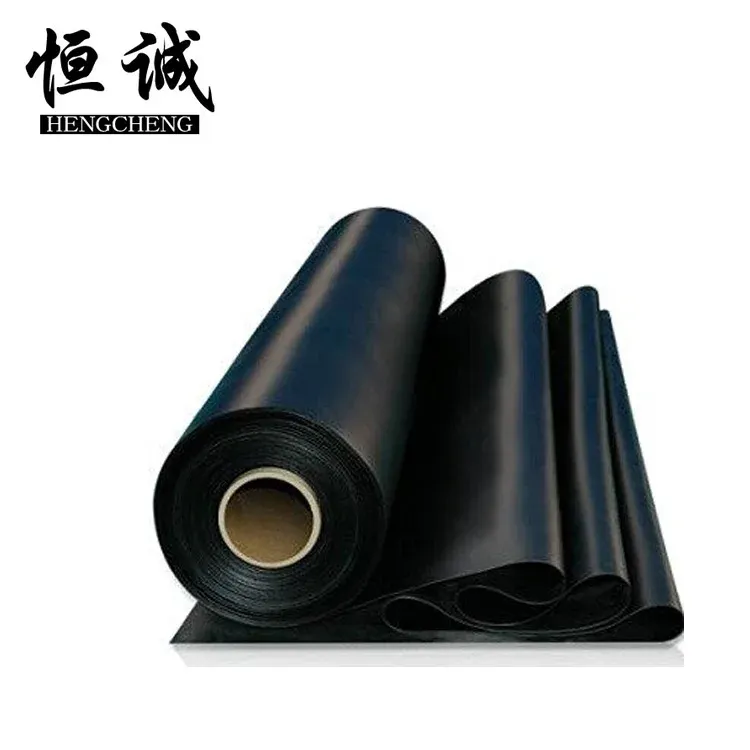

The rubber compound is often reinforced with materials like steel or fabric to enhance its mechanical strength and durability The rubber compound is often reinforced with materials like steel or fabric to enhance its mechanical strength and durability

The rubber compound is often reinforced with materials like steel or fabric to enhance its mechanical strength and durability The rubber compound is often reinforced with materials like steel or fabric to enhance its mechanical strength and durability